Founded in 1995, Dongrun Casting Industry Co., Ltd. has dedicated over 30 years to the casting industry, serving as a one-stop solution provider integrating precision aluminum casting, machining, surface treatment, and testing certification. With technological innovation at its core and strict quality control as its foundation, the company delivers end-to-end services from casting blanks to finished products for global clients.

Core Business and Technical Capabilities

Diversified Casting Processes

- Sand Casting: Ideal for complex structures and small-batch customized needs, professional in supporting cast aluminum alloys.

- Gravity Casting: Using metal molds for gravity pouring to achieve high-precision, low-porosity aluminum and zinc alloy parts.

- Low-Pressure Die Casting: Metal liquid is poured under low pressure to improve casting density, particularly suitable for high-strength applications in aerospace and automotive components.

- High-Pressure Die Casting: Equipped with multiple large-scale die casting machines, capable of producing thin-walled and complex geometric precision parts. The maximum mold size reaches 1500 mm, with an annual capacity exceeding 800 tons.

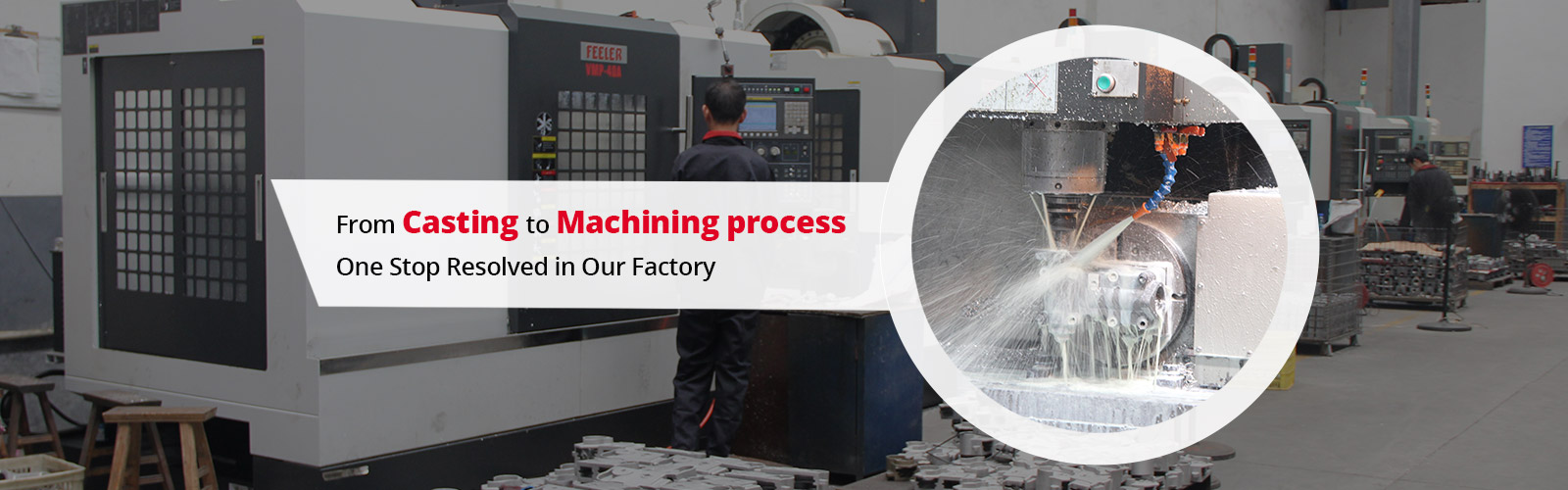

Precision Machining Services

- Equipped with CNC machining centers, CNC lathes, and grinders, achieving an accuracy level of IT6. We support rapid response from single-piece sampling to mass production.

- Provide rapid prototyping services, completing sample delivery within 72 hours using 3D printing and digital modeling technologies. We can also simultaneously provide Initial Sample Inspection Reports (ISIR) and Production Part Approval Process documents (PPAP) to ensure compliance with international standards such as IATF 16949.

Full-Flow Surface Treatment

- Pre-treatment: Shot blasting and sandblasting to ensure raw surface roughness reaches Ra3.2-12.5μm.

- Protective Coatings:

- Powder Coating: Covers the full RAL color range, with uniform film thickness (±10μm) and salt spray resistance exceeding 1,000 hours.

- E-Coating: Suitable for anti-corrosion of complex inner cavities, with film adhesion meeting ISO grade 4B standards.

- Plating: Including zinc plating, nickel plating, and chrome plating, compliant with RoHS and REACH environmental regulations.

Comprehensive Quality Assurance

- In-House Laboratory: Capable of providing raw material reports, heat treatment reports, leak test reports, and dimensional inspection reports as required by clients.

- Quality Control System: Certified to ISO 9001:2015 and IATF 16949, with full-process traceability from material procurement to shipment, ensuring defect rates remain below 0.3%.

Why Choose Dongrun Casting?

- One-Stop Service: Eliminate supply chain fragmentation by integrating casting, machining, and surface treatment.

- Rapid Turnaround: 72-hour prototyping and flexible production scheduling for urgent orders.

- Global Compliance: Products meet ASTM, DIN, JIS, and other international standards, exported to over 30 countries in Europe, America, and Southeast Asia.