Gravity Die Casting VS Pressure Die Casting: What Are the Differences?

Die casting is a widely utilized casting process, but understanding the distinction between Gravity Die Casting and Pressure Die Casting is essential. Both are casting methods, and we'll delve into the variances while discussing the selection criteria.

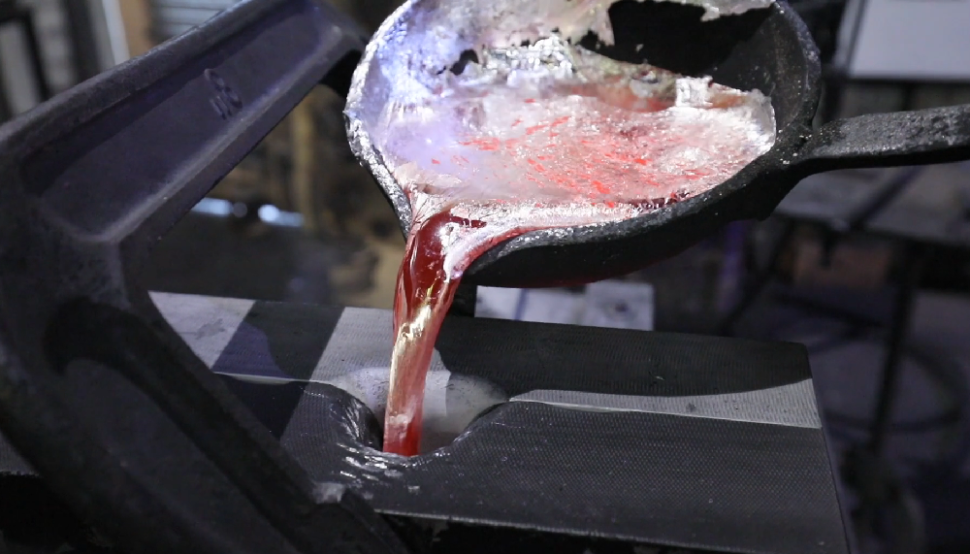

In both forms of Die Casting, a metal mold is employed to introduce non-ferrous molten metal, typically an alloy of Aluminum, Zinc, Magnesium, Lead, Tin, or Copper. The primary contrast between Gravity Die Casting (also known as Permanent Mould Casting) and Pressure Die Casting lies in how molten metal reaches the mold. In Gravity Die Casting, molten metal is poured into the mold from above, filling it from the bottom up solely under gravitational force. Conversely, in Pressure Die Casting, molten metal is injected into the mold under significant pressure (ranging from 1500 to 25,400 psi), and this pressure is maintained until the casting solidifies.

The high-pressure injection in Pressure Die Casting enables rapid alloy injection, coupled with the highly automated nature of the process, resulting in high productivity and reduced potential for human error. However, Gravity Die Casting, relying on gravity to fill the mold, is slower and less suited for long production runs.

Pressure Die Casting's requirement for delivering molten metal under pressure in a highly automated process makes it complex and costly to set up. Additionally, there can be a notable difference in tooling costs, as Pressure Die Casting molds require hardened Steel, often with internal cooling channels. In contrast, Gravity Die Casting molds can be made from Cast Iron, with lower cycling rates preventing heat buildup and allowing rapid chilling of the casting. Gravity Die Casting also offers the advantage of using sand cores to create internal voids not possible with Pressure Die Casting.

Each process yields different casting qualities. Pressure Die Casting, with its rapid mold filling under pressure, achieves precise and complex castings that are dimensionally accurate, with smoother as-cast surfaces requiring less secondary machining. Gravity Die Casting, while not matching these attributes, has the advantage of less turbulence during mold filling, reducing trapped air in the casting. This makes Gravity Die Casting preferable for applications requiring subsequent heat treatment, although Pressure Die Castings are stronger in the as-cast state.

In summary, Pressure Die Casting involves higher setup costs and is less flexible due to its complexity. However, its potential for high productivity makes it suitable for stable, high-volume production runs, leading to lower unit costs. The choice between Gravity Die Casting and Pressure Die Casting depends on design specifications, component geometry, production run, and economic factors. We offer both options, along with alternatives such as Sand Casting, Investment Casting, Lost Foam Casting, and Shell Mould Casting.

Dongrun Casting have 20000 square meters facility houses and 200 production & test equipment, From quotation and tooling design to casting and finished machining, we can work with you at every stage. We serves wide range of industries-from Fortune 500 corporations to small and midsize OEMs. Our products includes: Automotive&Trucking, Electric Utility & Communications, Metering System, Hydraulic Industry, Medical Devices, Lighting, Fuel and Gas Pressure, Furniture parts.

More Details : www.dongruncasting.com