Guide to Casting Parts: Understanding the Process and Ensuring Quality

Casting is a fundamental manufacturing process used to create complex shapes and structures by pouring molten metal into molds. Whether you're venturing into aluminum casting, sand casting, gravity casting, permanent mold casting, or low pressure die casting, understanding the process is crucial to achieving high-quality results. At Dongrun Casting, with over 25 years of expertise in the aluminum casting industry, we have encountered many clients who come to us after facing issues with poor quality castings from other suppliers. Our goal is to provide not just reasonable pricing but also reliable solutions from casting to machining. Let’s delve into the casting process to better understand how it works and what makes a casting project successful.

The Basics of Casting

Casting involves creating a mold, filling it with molten metal, and allowing the metal to solidify before removing the mold. The process is versatile and can be used for a wide range of metals, including aluminum, iron, steel, magnesium alloys, brass, bronze, and various pot metal alloys that may include lead, tin, and zinc. Aluminum casting, in particular, is highly popular due to aluminum's lightweight properties, corrosion resistance, and versatility in applications such as automotive parts, aerospace components, and industrial machinery.

The Role of Cores in Casting

To produce internal cavities or complex geometries—such as liquid cooling channels in engine blocks or cylinder heads—cores are used. These are negative forms that create hollow spaces within the casting. Typically made of sand, cores are inserted into the mold before pouring molten metal. However, designing castings that minimize or eliminate the need for cores is often preferred since cores add extra setup time and cost.

The Sand Casting Process

Sand casting is one of the most widely used casting methods due to its cost-effectiveness and ability to produce large and complex parts. Here’s how it works:

1. Creating the Mold: A sand mold is formed by packing sand around a pattern that represents the desired shape of the part.

2. Inserting Cores: If internal cavities are required, sand cores are inserted into the mold.

3. Pouring Molten Metal: The mold is filled with molten metal—such as aluminum or other alloys—at the appropriate temperature.

4. Cooling: The filled mold is left to cool until the metal solidifies.

5. Removing the Casting: Once cooled, the sand mold is broken away to reveal the rough casting.

Sand casting is ideal for low to medium production volumes and can accommodate a wide range of sizes and weights. However, it may require additional machining to achieve precise tolerances.

Gravity Casting and Permanent Mold Casting

Gravity casting and permanent mold casting are closely related processes that involve pouring molten metal into a reusable metal mold under the force of gravity. These methods are particularly suited for aluminum casting and are known for producing parts with excellent surface finishes and dimensional accuracy.

Gravity Casting: In this process, molten metal flows naturally into the mold cavity due to gravity. It’s commonly used for producing parts such as automotive components and industrial equipment.

Permanent Mold Casting: Unlike sand molds, permanent molds are made of durable metal materials like steel or cast iron. They can be reused multiple times, making this method cost-effective for high-volume production runs.

Both gravity casting and permanent mold casting eliminate the need for disposable molds, reducing waste and improving efficiency.

Low Pressure Die Casting

Low pressure die casting is another advanced method used primarily for aluminum casting. In this process, molten metal is forced into the mold cavity under low pressure (typically 0.7–1.5 bar). This controlled pressure ensures better filling of the mold and reduces porosity in the final part. Low pressure die casting is ideal for producing intricate designs with thin walls and high strength requirements. It’s commonly used in industries such as automotive and aerospace.

Addressing Common Casting Challenges

While casting offers numerous advantages, challenges such as poor quality or defects can arise if proper procedures are not followed. Here are some key aspects to consider:

1. Floating the Mold: When working with heavier metals like iron or lead in sand casting, there’s a risk of "floating" the mold. This occurs when the pressure of the molten metal pushes the sand above the mold cavity out of shape, leading to casting failure. To prevent this, heavy plates can be placed on top of the mold during pouring.

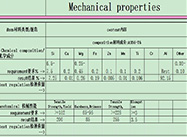

2. Stress Relief and Heat Treatment: After casting, internal stresses may develop due to uneven cooling rates. Heat treatments such as quenching in water or oil can relieve these stresses while enhancing hardness and strength—particularly for steel or iron castings.

3. Surface Finishing: Techniques like shot peening can improve surface quality by adding resistance to tensile cracking and smoothing rough areas.

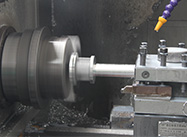

4. Precision Machining: For parts requiring tight tolerances or critical dimensions—such as engine blocks—additional machining operations like milling or boring are performed after casting.

Ensuring Quality in Aluminum Casting Projects

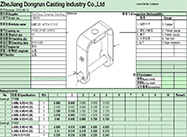

Choosing the right supplier is essential for ensuring high-quality castings. At Dongrun Casting, we focus on delivering excellence through every step of the process—from designing molds to machining finished parts. Here’s how we ensure quality:

Expertise in Aluminum Casting: With decades of experience, we specialize in various aluminum casting methods, including sand casting, gravity casting, permanent mold casting, and low pressure die casting.

Advanced Equipment: We use state-of-the-art machinery and techniques to achieve precise results.

Customized Solutions: Every project is unique, so we tailor our processes to meet your specific requirements.

Thorough Inspection: Each casting undergoes rigorous quality checks to ensure it meets industry standards and client expectations.

Understanding the nuances of aluminum casting and its various methods—such as sand casting, gravity casting, permanent mold casting, and low pressure die casting—is key to achieving successful results in your projects. By partnering with an experienced supplier like Dongrun Casting, you can avoid common pitfalls such as poor quality or defects while benefiting from reliable solutions at reasonable prices.

Whether you’re producing engine components, industrial machinery parts, or custom designs, we’re here to guide you through every step of the process—from initial consultation to final delivery. Contact us today to discuss your next casting project and experience the difference that expertise and dedication can make!

|  |  |  |

| Sand Core Equipments | Sand Core Productions | Finshed Sand Cores | Put Sand Cores Into Mould |

|  |  |  |

Put Sand cores Into | Degassing Equipment | Before Pouring,Checking | Hydrogen Measuring |

|  |  |  |

| Pouring-Gravity Casting | Pouring-Sand Casting | Low pressure Die Casting | Pouring-Die Casting |

|  |  |  |

| Cutting the Gate | Grinding | Heat Treatment | Shot Blasting Equipment |

|  |  |  |

Raw Casting After | Waiting Machining | CNC Equipment | CNC Machining 3axis and 4axis |

|  |  |  |

| CNC Lathe | Lathe Machining Process | Inspection Table | Guage Inspection |

|  |  |  |

| Guage Inspection | CMM Inspection | Final Inspection and | Dimension Report for |

| |||

Mechanical properties |