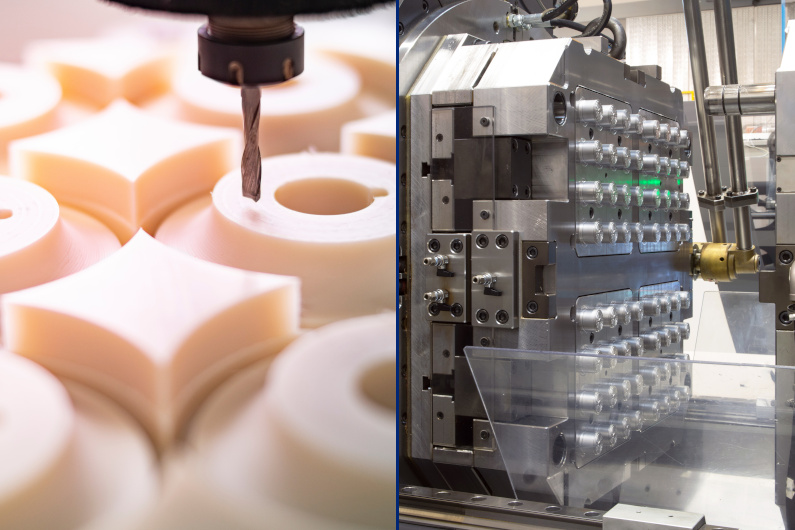

CNC Machining vs Plastic Injection Molding

From prototyping to mass production, selecting the right manufacturing technique significantly influences your time to market, as well as the quality and cost-effectiveness of your final product. CNC machining and plastic injection molding are two commonly used methods, each offering unique advantages and applications. Understanding their differences is crucial to determining the most suitable process for your needs. Explore the comparison between CNC Machining and Plastic Injection Molding, and discover a third option worth considering.

What is CNC Machining?

CNC machining involves the automated cutting, shaping, and production of high-precision items from various materials using computer numerical control (CNC) machines. These machines execute pre-programmed commands to control the movement of cutting tools, enabling tasks such as milling, turning, drilling, routing, and grinding. CNC machining finds extensive use in industries like aerospace, automotive, and industrial equipment manufacturing for producing complex, high-quality parts with exceptional precision.

What is Plastic Injection Molding?

Plastic injection molding creates parts and components by injecting molten plastic material into a mold cavity under high pressure. Upon cooling and solidification within the mold, the plastic adopts the shape of the cavity, forming the desired object. This process, highly versatile and capable of producing intricate shapes with precise dimensions and tight tolerances, serves various industries including automotive, aerospace, consumer goods, medical devices, and electronics manufacturing.

Comparing CNC Machining vs Plastic Injection Molding

The choice between CNC machining and plastic injection molding depends on factors such as material compatibility, desired quantity, and part complexity. Here's a closer examination of their respective advantages and disadvantages:

CNC Machining Pros:

Wide material compatibility including metal, wood, plastic, and others.

Modular design allows easy customization for changing requirements.

Ability to use precise, small-diameter tools for accuracy.

Automated processes enable fast and efficient manufacturing.

CNC Machining Cons:

High initial cost and maintenance expenses.

Requires training for operation and programming.

Outsourcing may mitigate costs but introduces dependency.

Plastic Injection Molding Pros:

Rapid production of large volumes with quick solidification.

Minimal cleanup required, enabling swift shipment.

Cost-effective for high-volume production runs.

Plastic Injection Molding Cons:

Reworking parts is challenging and costly.

High upfront costs due to tooling and mold creation.

Prone to surface flaws and limited to plastic materials.

Alternative: 3D Printing

In addition to CNC machining and plastic injection molding, 3D printing offers a viable alternative. As an additive manufacturing process, 3D printing excels in handling complex geometries and customized parts with minimal tooling requirements. It facilitates rapid prototyping and is cost-effective for low-volume production. While 3D printing may not match the durability and precision of CNC machining or injection molding, it presents advantages in terms of material variety, setup costs, and rapid prototyping capabilities.

Conclusion

The choice between CNC machining, plastic injection molding, and 3D printing depends on your specific requirements, including material compatibility, desired quantity, precision, and budget considerations. By understanding the strengths and limitations of each method, you can make an informed decision to optimize your manufacturing process.

Dongrun Casting have 20000 square meters facility houses and 200 production & test equipment, From quotation and tooling design to casting and finished machining, we can work with you at every stage. We serves wide range of industries-from Fortune 500 corporations to small and midsize OEMs. Our products includes: Automotive&Trucking, Electric Utility & Communications, Metering System, Hydraulic Industry, Medical Devices, Lighting, Fuel and Gas Pressure, Furniture parts.

More Details : www.dongruncasting.com