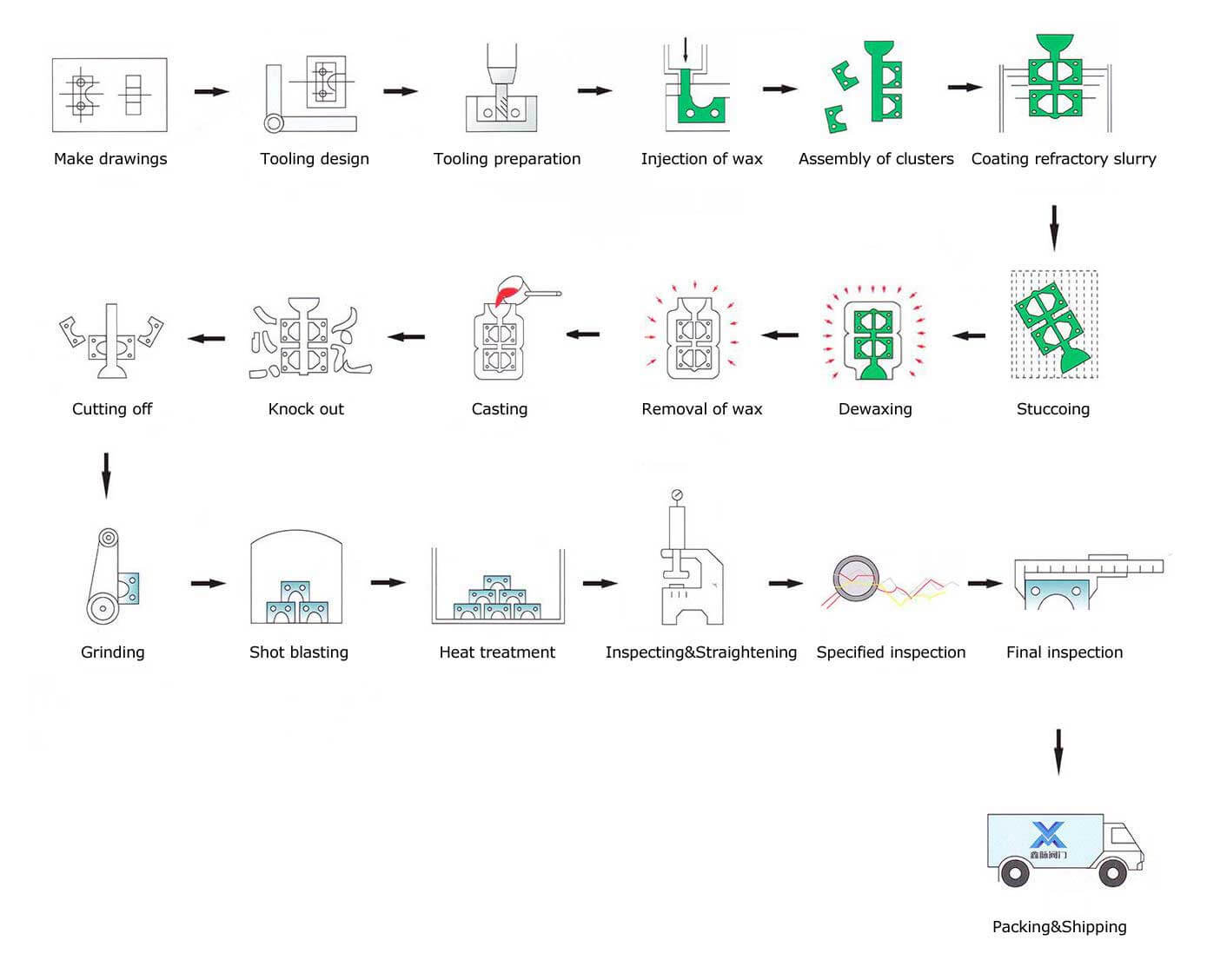

What are the steps of lost waxing, casting and wax injection process? Die lost waxing casting is one of the glass manufacturing processes. The main process is to heat the glass to high temperature and flow into the preform mold. Since the mold shell is obtained by taking out the wax mold after heating, it is called lost wax casting.

After the mold is opened, wax injection can be carried out. Pay attention to wax temperature, pressure, mold compression and other factors during wax filling operation.

After the wax mold is taken out, it should be carefully checked. If there are serious problems such as missing edges and broken legs, this wax model is a waste product. For some minor defects, wax pattern repair shall be carried out.

The wax used to make wax models is generally about 60 ℃, and the wax injection temperature is about 65 ℃. There are also paraffin waxes of other colors with slightly different properties. Wax temperature and wax injection pressure are determined by the wax injection machine. Wax injection machines are generally divided into two categories: pneumatic and vacuum.

The pressure in the wax cylinder of the wax injector is usually provided by an external air pump, which should generally be kept between 0.5~0.7at (or kgf/cm2), that is, 0.051~0.071Bar. It can also be adjusted according to the volume and complexity of the wax model.

Before waxing, open the plastic mold and check whether the plastic mold is complete and clean. If the plastic mold has been used, spray a dewaxing agent (or a small amount of talcum powder) on the plastic mold, especially on thin and complex parts, to facilitate the dewaxing mold; Secondly, preheat the wax injection machine, turn on the air pump, adjust the pressure and temperature, and perform precision casting.

During wax injection, the plywood (which can be plexiglass plate, wood plate, aluminum plate, etc.) shall be clamped by hand. Pay attention to the distribution of fingers to make the rubber mold pressed evenly; Do not move your hand behind your mouth. Gently step on the wax injection switch with your foot and release it immediately. After staying for 1-2 seconds, put the plastic mold in, open the plastic mold (if the plastic mold has a bottom, pull out the bottom of the mold first), and take out the wax mold.

The wax injection principle of the two types of wax injection machines is basically the same, that is, the melted wax is injected into the plastic mold by using air pressure. The difference is that the vacuum wax injector can vacuum the plastic mold first, and then inject wax into the plastic mold, while the pneumatic wax injector can only inject wax directly into the plastic mold. Therefore, in general, the operation of vacuum wax injector is easy to master, while the pneumatic wax injector requires some experience,

The heater and temperature sensing device used on the waxing machine can reach and maintain a certain temperature. Generally, the wax temperature of the wax injector should be kept at 70~75 ℃ to ensure the fluidity of the wax liquid. If the temperature is too low, the wax liquid is not easy to be injected into the wax mold, resulting in incomplete wax mold; On the contrary, if the wax temperature is too high, it will cause the wax to overflow from the gap of the plastic mold or the wax injection port, which is easy to form flash. Or burn your fingers.

ZheJiang Dongrun Casting Industry Co,.Ltd was built in 1995, We have been in the casting industry for more than 25 years. No matter what type of molding you need done, we are the right supplier for your jobs. Unlike other of our competition, we offer four types of castings.

Dongrun Casting have 20000 square meters facility houses and 200 production & test equipment, From quotation and tooling design to casting and finished machining, we can work with you at every stage. We serves wide range of industries-from Fortune 500 corporations to small and midsize OEMs. Our products includes:

❖ HVAC | ❖ Architectural parts |

Browse our online showroom to see what we can do for you. And then E-mail:dongrun@dongruncasting.com us your specifications or inquiries today