Sand Casting: An Overview

The sand casting process, also known as sand molded casting, is a metal casting technique that utilizes sand as the mold material. This method accounts for over 60% of all metal castings. Let's delve into the key aspects of sand casting.

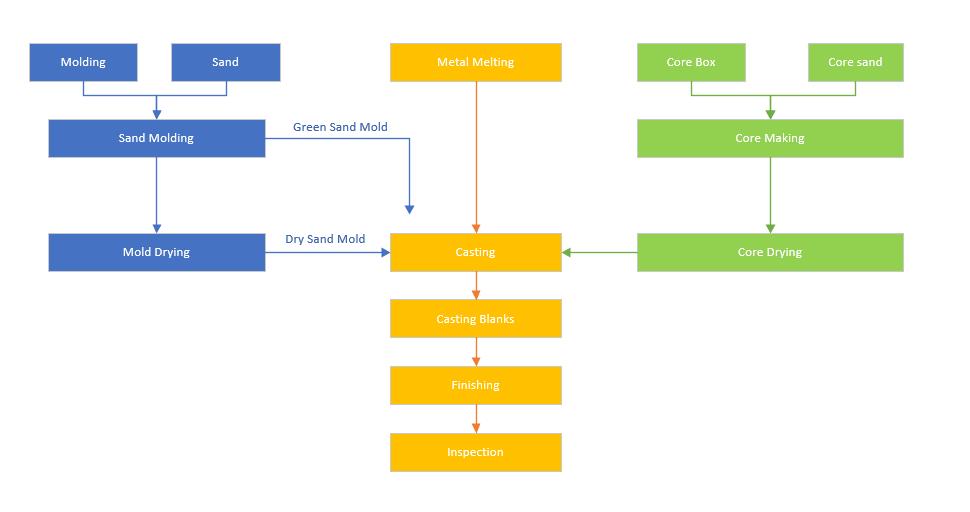

Process Flows of Sand Casting:

The general flow of the sand casting process involves four main steps: sand making, core making, casting, and post-processing. Refer to the diagram below for a visual representation of the process flows.

Insert Sand Casting Process Flows Diagram

Insert Sand Casting Process Flows Diagram

Parameters to Consider in the Sand Casting Process:

Machining Allowance:

Design consideration for surfaces requiring machining on the casting.

Dependent on casting alloy, molding method, size of the casting, and location of machined surfaces in the mold.

Draft Angle:

Slope on the vertical mold wall for easy removal of the casting.

Facilitates the extraction of the casting from the mold.

Casting Fillet:

Designing fillets at joints and corners to prevent stress, cracks, and damage to sharp corners.

A measure to avoid the formation of sand holes.

Core Head:

Essential for positioning, fixing, and venting of the core in both the mold and core.

Shrinkage Allowance:

Compensation for dimensions affected by shrinkage after pouring.

Advantages of Sand Casting:

Abundant and Inexpensive Material:

Clay, a primary component of green sand, is abundant and recyclable.

Short Casting Mold Production Period:

High molding efficiency due to a short production period for casting molds.

Long Service Life of Molding Sand:

Molding sand has a prolonged service life.

Versatility:

Applicable to small or large, simple or complex workpieces.

Suitable for individual production or mass production.

Disadvantages of Sand Casting:

Single Use of Sand Molds:

Each sand mold can only be used once, requiring remolding and reducing production efficiency.

Lower Rigidity and Dimensional Accuracy:

Casting exhibits lower rigidity, leading to poor dimensional accuracy.

Susceptibility to Defects:

Prone to defects such as sand washing, sand trapping, and blowholes.

In summary, while sand casting offers advantages such as cost-effectiveness and versatility, it comes with challenges related to mold reusability and dimensional accuracy. Understanding these aspects is crucial for effective utilization of the sand casting process.

Dongrun Casting have 20000 square meters facility houses and 200 production & test equipment, From quotation and tooling design to casting and finished machining, we can work with you at every stage. We serves wide range of industries-from Fortune 500 corporations to small and midsize OEMs. Our products includes: Automotive&Trucking, Electric Utility & Communications, Metering System, Hydraulic Industry, Medical Devices, Lighting, Fuel and Gas Pressure, Furniture parts.

More Details : www.dongruncasting.com