The difference between porosity and shrinkage in the casting process

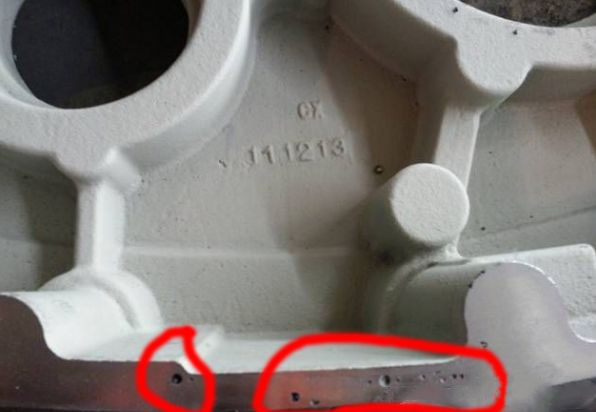

In the casting production, casting porosity and casting shrinkage are sometimes accompanied by, and sometimes exist independently. When the appearance of porosity and shrinkage, we quickly determine whether the defect is porous, or shrinkage is necessary to solve the problem. To quickly determine these two defects, it is necessary to first understand their characteristics very well. Today, we will teach you to quickly determine the pore and shrinkage defects from the recognition of their characteristics.

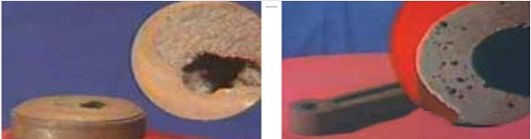

Pore class defects and prevention methods in the casting production, hole class defects are common defects, but also to the foundry to cause greater losses one of the defects. Hole class defects are divided into porosity and shrinkage. Porosity is mostly due to the intrusion of metal liquid, wrapped in, involved in the gas to.

Casting porosity appears in different locations on the casting, the reasons for its generation are also different. This requires our casting technicians in determining the cause of porosity defects, to master the principle of the occurrence of various types of pores, with what characteristics. Only then can we prescribe the right remedy to solve the occurrence of porosity defects.

Here, we look at the different reasons for the generation of porosity characteristics: (1) involved in the porosity: metal liquid in the filling process due to the involvement of gas and the formation of pores in the casting, more isolated round or oval large pores, the location is not fixed, generally biased castings in the upper.

(2) intrusion pore: by the type, core, paint, core support, cold iron pores generated by the invasion of the casting surface and the formation of pores, mostly pear-shaped or oval, larger size, smooth wall, the surface is more oxidation color.

(3) reaction pore: by the metal liquid between certain internal components or metal liquid and the type, the core at the interface of the chemical reaction and the formation of a group distribution of pores. Needle-shaped or waist round reaction pores located on the surface of the casting is called surface needle hollow and subcutaneous pores, by the metal liquid and the type, core coating interface reaction to; scattered or in groups distributed throughout the casting section or a local area of the needle reaction pores.

Causes of formation

(1) Due to dampness of furnace material, rust, oil, humidity of climate, melting tools and pouring ladle not dried, improper composition of metal liquid, alloy liquid for refining and under-refining, so that the metal liquid contains a large amount of gas or gaseous substances, resulting in precipitation of gas holes or reaction gas holes in the casting.

(2) type, core is not fully dried, poor permeability, poor ventilation, containing too much water and gas-generating substances, paint is not dried or contains too much gas-generating ingredients, cold iron, core support with rust spots, oil or not dried, poor exhaust of the metal type, the formation of intrusion pores in the casting.

(3) unreasonable pouring system, pouring and filling speed is too fast, the metal exhaust poor, so that the metal liquid in the pouring and filling process to produce turbulence, vortex or broken flow and involved in the gas, the formation of involved in the casting porosity.

(4) alloy liquid can easily absorb gas, in the melting and pouring process did not take effective refining, protection and purification measures, so that the metal liquid contains a large amount of gas, slag and gas trapped components, in the filling and solidification process to form precipitation pores and reaction pores.

(5) Improper preparation of sand, core and paint, and metal liquid interface reaction, the formation of surface pinhole and subcutaneous pores.

(6) The pouring temperature is too low, the temperature of the metal type is too low, the metal liquid slag removal is not good, the viscosity is too high, so that the gas involved in the pouring and filling process and the gas precipitated by the metal liquid can not be discharged from the casting or float to the riser or air outlet.

(7) In the humid season when melting the alloy which is easy to absorb gas, the alloy liquid absorbs a lot of gas, causing the castings to be scrapped in batches.

(8) resin sand resin and curing agent to add too much, resin fluorine content is too high, the original sand and recycled sand angular coefficient is too high, particle size is too fine, scorching reduction and micro powder content is too high, so that the air emission of the sand is too high, the permeability is too low

Prevention methods (1) non-ferrous alloy melting, furnace charge, solvent, tools and pouring ladle should be fully preheated and dried, de-rusted and de-oiled, and the addition of multiple remelting furnace charge should be appropriately limited.

(2) to prevent the metal liquid in the melting process of excessive oxidation and gas absorption, to deoxidation, gas removal and slag removal, the surface of the metal melt pool in the pouring ladle plus cover solvent to prevent the metal secondary oxidation, gas absorption and harmful impurities back to the melt pool. When deoxidizing cast steel and cast iron with aluminum, the residual aluminum content should be strictly controlled, and the steel with serious gas absorption tendency should avoid deoxidizing with aluminum as much as possible, and AVD, VOD, porous plug blowing inert gas, powder spraying method, etc. can be used to refine the steel outside the furnace to remove the gas and harmful impurities in the steel; for ductile iron, desulfurization should be strengthened to reduce the flow of the original soup, and to ensure the premise of spheroidization, minimize the spheroidizing agent Add the amount of cast iron, reduce the amount of residual magnesium, and strengthen the breeding process.

(3) When pouring, the metal liquid should not break the flow, the filling speed should not be too high, the casting pouring position and the setting of the pouring system should ensure that the metal liquid fills the cavity smoothly and facilitate the smooth discharge of gas in the open cavity.

(4) casting, should ensure that the casting and core exhaust smooth, sand core to open the exhaust channel, to fill the core head gap when closing the type, so as not to drill into the metal liquid blocking the exhaust channel.

(5) Increase the height of the straight sprue to improve the static pressure of the metal liquid filling.

(6) Reduce the amount of resin and curing agent added to resin sand, use low nitrogen or nitrogen-free resin and round shape material, moderate particle size, low scorching and micro powder content of the original sand and recycled sand, in order to reduce the amount of resin gas, improve the permeability of resin sand.

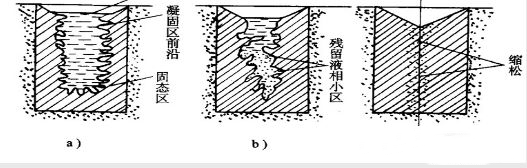

Shrinkage class defects and prevention methods and castings produce shrinkage, shrinkage loose, there are many reasons, there are castings and mold design reasons, there are sand box design is not appropriate reasons, there are pouring mouth design reasons, there are type of sand type to avoid displacement reasons, in addition, there are system reasons, there are metal chemical composition of improper deployment reasons, there are melting link improper operation reasons, there are also pouring reasons.

Because of the many causes of casting shrinkage, it is often time-consuming to find the root cause. How to quickly determine the internal causes of casting shrinkage generation, which requires us to compare more cases of casting shrinkage defects, familiar with the theoretical characteristics, strengthen the study, so as to improve the understanding of such defects and the ability to solve.

ZheJiang Dongrun Casting Industry Co,.Ltd was built in 1995, We have been in the casting industry for more than 25 years. No matter what type of molding you need done, we are the right supplier for your jobs. Unlike other of our competition, we offer four types of castings.

Dongrun Casting have 20000 square meters facility houses and 200 production & test equipment, From quotation and tooling design to casting and finished machining, we can work with you at every stage. We serves wide range of industries-from Fortune 500 corporations to small and midsize OEMs. Our products includes:

❖ HVAC | ❖ Architectural parts |

Browse our online showroom to see what we can do for you. And then E-mail:dongrun@dongruncasting.com us your specifications or inquiries today