Sand casting (also known as sand mold casting): a casting process in which molten liquid metal is formed in a sand mold. Steel, iron and most non-ferrous alloy castings can be obtained by sand casting. Due to the low cost and availability of the molding materials used in sand casting, the casting mold is easy to manufacture, suitable for single-piece production and small batch production of castings. For a long time, it has been a metal Basic process in casting production.

Process cost: mold cost (low), unit cost (medium)

Typical products: metal fixing parts for construction, vehicle parts, furniture, lamps, engines, etc.

Suitable output: suitable for single piece and small batch production

Quality: The molding surface has low accuracy, but it is suitable for casting hollow and porous parts

Speed: The cycle time of each piece is moderate (5min-30min), depending on the proficiency of the operator

Applicable materials

1. Suitable for ferrous metals and non-ferrous alloys, the most commonly used materials are: iron, steel, copper alloy, aluminum alloy

2. Magnesium has also been increasingly used in sand casting in recent years, especially in the aerospace field

Design considerations

1. The draft angle should be controlled between 1°-5° (2° is usually more appropriate)

2. The wall thickness of the parts should be controlled between 2.5mm-130mm (1in-5.12in)

3. Different metals have different cooling shrinkage rates. For example, for parts of the same volume, the shrinkage of steel is almost twice that of aluminum and iron. The shrinkage of brass is 50% higher than that of aluminum. The shrinkage is proportional to the volume of the part.

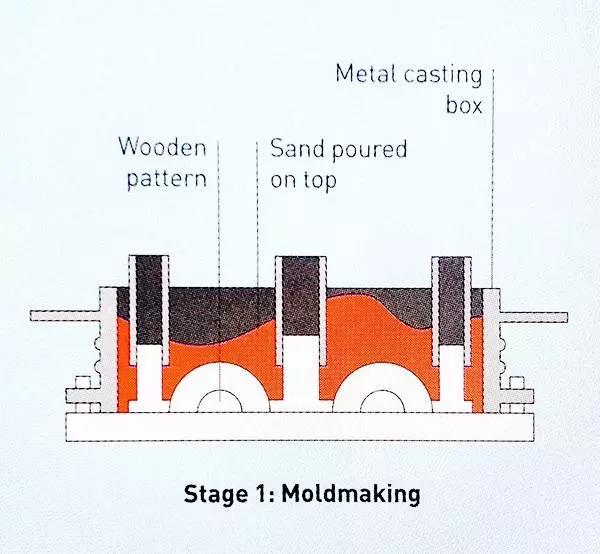

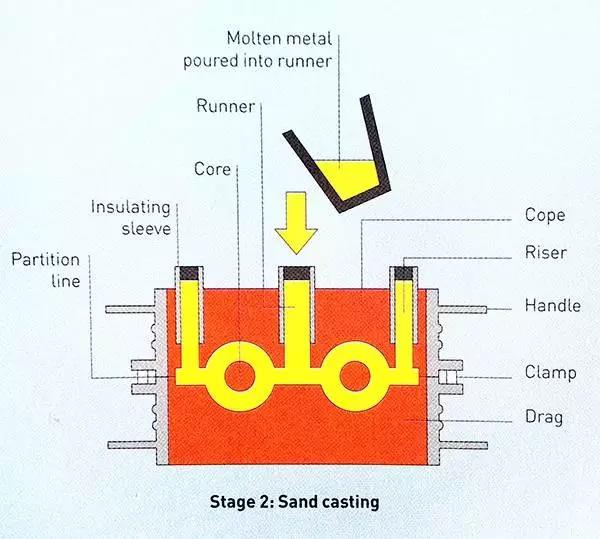

Detailed process description (graphics)

Step 1: Manufacture the sand mold: the mold is divided into two halves. Place the metal casting box on the wooden board with the pattern, pour the sand into the metal casting box, compact it and form the sand mold

Step 2: Sand casting: Pour the molten liquid metal into the cavity of the sand mold through the drainage port, wait for 5min-30min to cool and solidify the liquid metal, release the mold, and enter the subsequent grinding and trimming process

ZheJiang Dongrun Casting Industry Co,.Ltd was built in 1995, We have been in the casting industry for more than 25 years. No matter what type of molding you need done, we are the right supplier for your jobs. Unlike other of our competition, we offer four types of castings.

Dongrun Casting have 20000 square meters facility houses and 200 production & test equipment, From quotation and tooling design to casting and finished machining, we can work with you at every stage. We serves wide range of industries-from Fortune 500 corporations to small and midsize OEMs. Our products includes:

❖ HVAC | ❖ Architectural parts |

Browse our online showroom to see what we can do for you. And then E-mail:dongrun@dongruncasting.com us your specifications or inquiries today