What is CNC Machining?

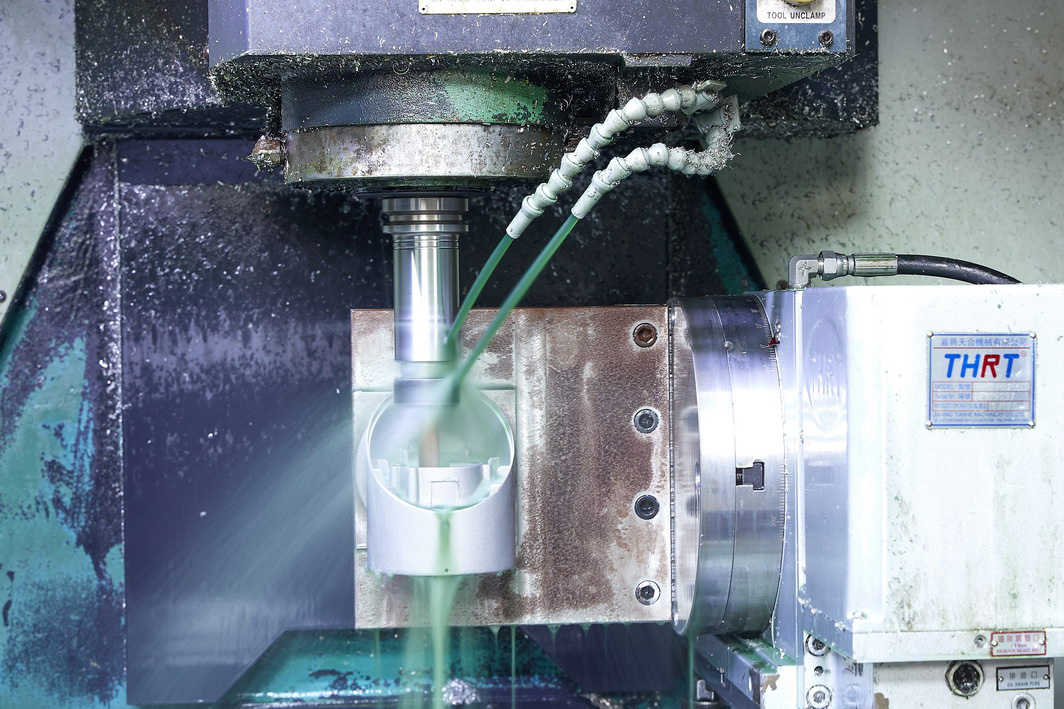

CNC machining, short for Computer Numerical Control machining,  is a sophisticated manufacturing process that utilizes computerized controls to operate and manipulate machine tools. It is instrumental in creating precision parts and prototypes across various industries, from automotive to aerospace. In Dongrun Casting factory, we are training the operators all the time. They can join in some skill games in China and take good achievement. I am sure our skilled operators can meet your requirements in drilling and tapping, milling, lathe work and CNC machining.

is a sophisticated manufacturing process that utilizes computerized controls to operate and manipulate machine tools. It is instrumental in creating precision parts and prototypes across various industries, from automotive to aerospace. In Dongrun Casting factory, we are training the operators all the time. They can join in some skill games in China and take good achievement. I am sure our skilled operators can meet your requirements in drilling and tapping, milling, lathe work and CNC machining.

CNC machining involves the use of computers to control machine tools such as lathes, mills, routers, and grinders. The process begins with a digital design, typically created using CAD (Computer-Aided Design) software. This design is then converted into a CNC program that directs the machine on how to cut, shape, and finish the material to achieve the desired specifications. The precision and automation offered by CNC machining make it ideal for producing complex geometries and intricate details with high repeatability.

Applications in Prototype Development

In the realm of prototype development, CNC machining plays a crucial role. It allows designers and engineers to quickly produce functional prototypes that can be tested for form, fit, and function. This rapid prototyping capability accelerates product development cycles by enabling quick iterations and refinements based on testing feedback. CNC machining ensures that prototypes are manufactured with high precision, closely mimicking the final product's characteristics.Before mass casting production, Dongrun Casting can offer you Prototype Development service as your drawings.

In the realm of prototype development, CNC machining plays a crucial role. It allows designers and engineers to quickly produce functional prototypes that can be tested for form, fit, and function. This rapid prototyping capability accelerates product development cycles by enabling quick iterations and refinements based on testing feedback. CNC machining ensures that prototypes are manufactured with high precision, closely mimicking the final product's characteristics.Before mass casting production, Dongrun Casting can offer you Prototype Development service as your drawings.

Applications in Aluminum Casting

Aluminum casting is a widely used manufacturing technique for producing lightweight and durable components. CNC machining complements this process by providing post-casting operations such as trimming, drilling, and finishing. After an aluminum component is cast, CNC machines can be employed to refine its dimensions and surface quality, ensuring it meets stringent specifications. The synergy between aluminum casting and CNC machining results in high-quality components suitable for demanding applications.

Dongrun Casting Industry Co., Ltd: A Leader in CNC Machining

Dongrun Casting Industry Co., Ltd stands out in the field of CNC machining with its advanced capabilities and commitment to quality.The company boasts 20 state-of-the-art 4-axis and 5-axis CNC machines, which offer enhanced flexibility and precision in machining complex parts. These machines are supported by Coordinate Measuring Machines (CMM), ensuring that every part produced is measured accurately against design specifications.

Advantages of Dongrun Casting Industry Co., Ltd

1. Comprehensive Quality Control: Dongrun Casting Industry Co., Ltdimplements rigorous quality control measures throughout the CNC machining process. This includes initial sample inspection, in-process checks, and final inspections. Key dimensions undergo 100% inspection to guarantee compliance with client requirements.

2. Advanced Equipment: The use of 4-axis and 5-axis CNC machines allows for multi-directional machining, which is essential for producing intricate components with complex geometries. This capability reduces the need for multiple setups and enhances production efficiency.

3. Precision and Reliability: With their CMM equipment, Dongrun ensures that every machined part meets precise dimensional tolerances. This commitment to precision minimizes errors and ensures that parts perform reliably in their intended applications.

4. Expertise in Aluminum Casting: Combining expertise in aluminum casting with advanced CNC machining capabilities enables Dongrun to deliver high-quality components tailored to specific industry needs.

CNC machining is a pivotal technology in modern manufacturing, offering precision, efficiency, and versatility. Its applications in prototype development and aluminum casting highlight its importance in accelerating product innovation and ensuring quality standards. Dongrun Casting Industry Co., Ltd exemplifies excellence in CNC machining through its advanced equipment, stringent quality control processes, and expertise in delivering reliable solutions for diverse industries.

Technical Specifications & File Compatibility

Supported File Formats: SolidWorks, Pro/E, UG, IGES, STEP (3D models),  and 2D drawings, ensuring seamless conversion of customer designs into machining instructions..

and 2D drawings, ensuring seamless conversion of customer designs into machining instructions..

Precision & Surface Finish:

- Tolerance control: ±0.001mm (suitable for precision assembly);

- Surface roughness: Ra0.8 (mirror-level finish).

Professional Team Structure

Machining Engineers: 3 senior engineers with over 10 years of experience in CNC programming and process planning, specializing in optimizing machining paths for complex projects.

Machining Staff: 20 certified operators, all qualified as senior CNC technicians, proficient in multi-brand equipment operation.

Production System & Equipment Matrix

Machining Shop Shifts: 3-shift operation (24/7 production) to ensure delivery efficiency.

Core Equipment List:

| Equipment Type | Quantity | Brands/Models | Typical Capabilities |

| CNC Machining Centers | 20 | HYUNDAI, FEELER, DOOSAN, YCM | 3-5 axis,max. machining size: 1600×1000×1000mm (ideal for large parts) |

| Milling Machines | 5 | High-precision vertical/horizontal | Complex plane, groove, and gearbox machining |

| Turning Machines | 8 | CNC horizontal lathes | Precision turning for shaft/disc parts |

| Drill & Tap Machines | 20+ | Imported servo-driven models | High-precision hole machining (min. Φ0.5mm) |