As the electric vehicle (EV) revolution accelerates, manufacturers face growing pressure to adopt advanced production technologies that meet the evolving demands of EV design. To maximize driving range, enhance safety, and optimize overall performance, EV components must be lightweight, structurally strong, and thermally efficient. Aluminum die casting has therefore become a critical manufacturing solution for modern EV platforms.

Why is Die Casting Critical for Electric Vehicles?

Weight Reduction and Structural Integration

Die casting plays a vital role in reducing vehicle weight, directly improving energy efficiency and driving range. By utilizing high-strength, low-density aluminum alloys, original equipment manufacturers (OEMs) can consolidate multiple welded or bolted components into a single integrated casting. With a density of approximately 2.7 g/cm³, aluminum castings can deliver up to 30% weight reduction compared to traditional steel assemblies in structural applications.

Large-scale structural components—such as battery enclosures, motor housings, and rear frame rails—benefit significantly from this integration. Fewer parts lead to shorter assembly times, lower manufacturing costs, and reduced failure points, while still meeting stringent crash and functional safety requirements, including ISO 26262 and individual OEM standards.

High Dimensional Accuracy and Repeatability

EV powertrain and chassis components demand extremely tight tolerances. Die casting provides exceptional dimensional accuracy and repeatability, typically achieving tolerances of ±0.05 mm for aluminum and ±0.02 mm for zinc alloys. This makes it well suited for high-volume production of motor housings, inverter housings, and thermal management components.

Such precision ensures consistent fit and alignment of critical parts, including electric motor stator housings, where tight concentricity is essential to minimize vibration, noise, and energy loss.

Enhanced Thermal and Electrical Performance

Aluminum die-casting alloys such as A360 and AlSi10Mg offer excellent thermal conductivity, often exceeding 100 W/m·K. This property makes them ideal for heat-sensitive EV components, including battery cooling plates, inverter heat sinks, and power electronics housings, where efficient heat dissipation is essential for performance and longevity.

For high-current applications, copper-based die-casting alloys are commonly used in components such as busbars, terminal housings, and charging modules, providing superior electrical conductivity and effective thermal management.

High Production Efficiency and Scalability

Die casting supports high production efficiency through short cycle times—often under 60 seconds per shot—while enabling complex geometries with thin wall sections (as low as 1.5 mm for aluminum and 0.8 mm for zinc). This capability makes die casting ideal for EV programs scaling from early development to mass production.

Advanced tooling materials, including H13 and P20 tool steels, allow die-casting molds to produce hundreds of thousands of parts with consistent quality and minimal wear, supporting long-term, high-volume manufacturing.

Key EV Components Made with Die Casting

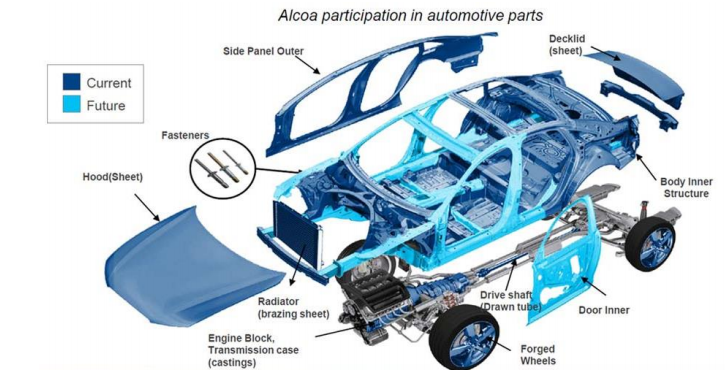

From the chassis to the powertrain, die-cast aluminum components are used extensively throughout modern electric vehicles. Thanks to their lightweight, high strength, and excellent thermal performance, EV die-cast parts are the preferred solution for many safety-critical and performance-driven applications.

Die-cast components play an essential role in nearly every major EV system.

Below is an overview of common EV parts produced using die casting and the reasons this process is ideally suited to each application:

| Component | Primary Function | Why Die Casting Is Ideal |

|---|---|---|

| Battery Enclosure (Tray) | Protects battery modules from impact, seals against dust and moisture, and supports thermal management | Enables complex, sealed structures with integrated cooling channels; high structural strength enhances battery safety |

| Motor Housing | Encloses the electric motor, provides structural support, and dissipates heat | Supports complex geometries with tight tolerances; excellent thermal conductivity ensures efficient motor cooling |

| Inverter & Converter Housings | Protect power electronics, provide EMI shielding, and manage heat | Acts as an effective heat sink and EMI shield; intricate designs reduce size and weight |

| Structural Components | Shock towers, subframes, A-pillars, and other load-bearing chassis elements | Enables part consolidation (e.g., giga casting), reduces vehicle weight, and improves torsional rigidity |

| Gearbox Housing | Encases the EV reduction gear system and supports torque transmission | High dimensional accuracy and mechanical strength ensure durability and low noise operation |

| ECU Housing | Protects electronic control units that manage vehicle systems | Lightweight yet durable; provides reliable EMI shielding for sensitive electronics |

Support Services for EV Component Development

For EV manufacturers and Tier 1 suppliers, we recommend integrated support services including:

- Design-for-manufacturing (DFM) and structural optimization

- Material selection and alloy performance validation

- Mold design, simulation, and lifecycle management

- Prototyping and low-volume pilot production

- Quality control, testing, and certification support

These services help accelerate development cycles, reduce risk, and ensure reliable, cost-effective production of EV die-cast components.

The Rise of Giga Casting: A Revolution in EV Manufacturing

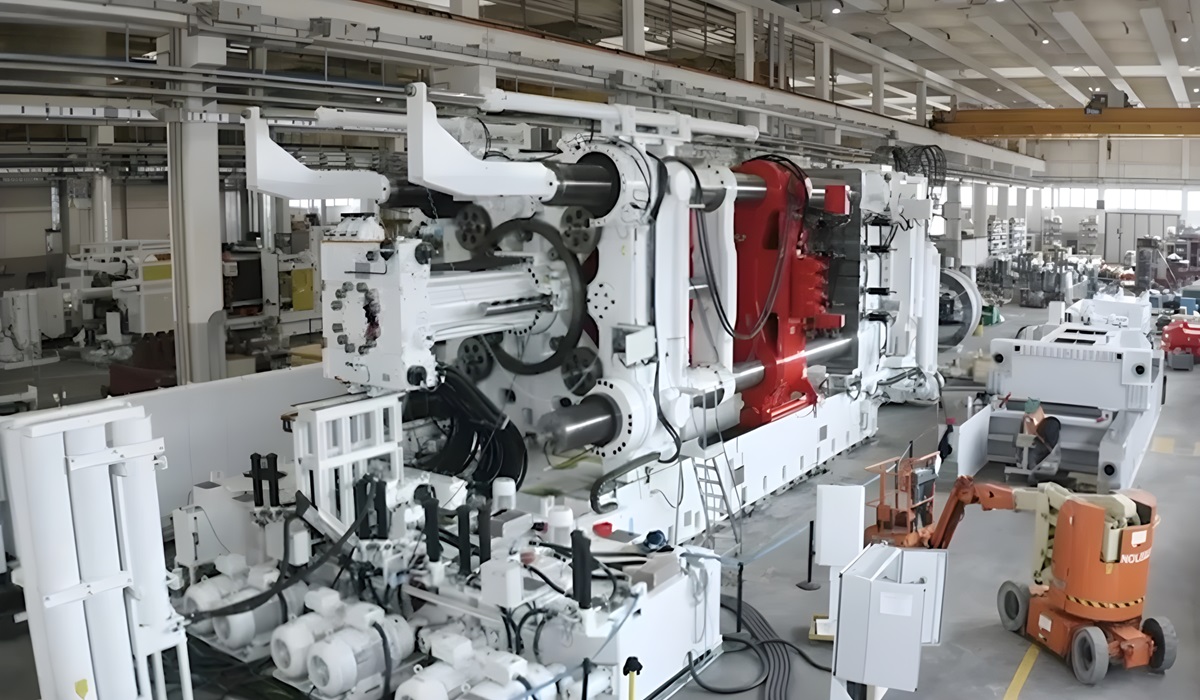

Giga casting is rapidly transforming the way electric vehicles are designed and built. By producing large, highly integrated aluminum structural components in a single die-casting operation, automakers are redefining vehicle architectures, manufacturing efficiency, and cost structures.

Originally popularized by leading EV manufacturers, giga casting replaces dozens—or even hundreds—of stamped and welded steel parts with one large aluminum casting. This shift significantly reduces part count, tooling complexity, and assembly steps, while improving structural rigidity and dimensional consistency.

Why Giga Casting Is Gaining Momentum

The adoption of giga casting is driven by several key advantages critical to EV production:

1. Dramatic Part Consolidation

A single giga-cast component can replace multiple subassemblies, reducing welding operations, fasteners, and potential failure points. This simplifies production lines and shortens assembly time.

2. Weight Reduction and Improved Efficiency

Aluminum giga castings offer substantial weight savings compared to multi-piece steel structures, directly contributing to improved driving range and battery efficiency.

3. Enhanced Structural Performance

Large integrated castings provide improved torsional rigidity and crash performance through optimized load paths and uniform material distribution.

4. Faster Production and Lower Manufacturing Costs

Fewer parts and assembly steps translate into shorter cycle times, lower labor costs, and reduced factory footprint—key advantages for high-volume EV platforms.

5. Design Freedom and Platform Flexibility

Giga casting enables complex geometries, integrated mounting points, and internal reinforcement structures that are difficult or impossible to achieve with traditional stamping and welding.

Applications of Giga Casting in EVs

Giga casting is commonly used for:

Front and rear underbody structures

Battery tray and floor assemblies

Integrated crash management systems

Suspension and mounting frameworks

These large structural components form the backbone of modern EV platforms.

Challenges and Future Outlook

Despite its advantages, giga casting presents challenges, including high initial investment in large-tonnage die-casting machines, advanced mold design, alloy development, and quality control. However, continuous advancements in vacuum die casting, real-time process monitoring, and heat-treatable aluminum alloys are rapidly addressing these concerns.

As EV production scales globally, giga casting is expected to become a standard manufacturing approach, enabling lighter, safer, and more cost-effective electric vehicles.

Dongrun Casting has 20000 square meters of facility houses and 200 production & test equipment, From quotation and tooling design to casting and finished machining, we can work with you at every stage. We serve a wide range of industries-from Fortune 500 corporations to small and midsize OEMs. Our products include Automotive&trucking, Electric Utility & Communications, Metering Systems, the Hydraulic Industry, Medical Devices, Lighting, Fuel and Gas Pressure, and Furniture parts.

More Details: www.dongruncasting.com