Investment Casting: A Comprehensive Guide to Precision Aluminum Casting Techniques

Investment casting, often referred to as "lost-wax casting," is a highly versatile and precise manufacturing process used to produce complex components with exceptional dimensional accuracy and surface finish. This technique has gained widespread popularity in the aluminum casting industry due to its ability to create intricate shapes that are difficult to achieve with other methods. In this article, we will explore the intricacies of investment casting while delving into related aluminum casting techniques, such as aluminum sand casting, aluminum gravity casting, permanent mold aluminum casting, and low pressure aluminum die casting.

What is Investment Casting?

Investment casting is a process that involves creating a wax pattern that is coated with a ceramic shell to form a mold. Once the ceramic mold is hardened, the wax is melted and drained away, leaving a cavity that can be filled with molten metal. This method is particularly advantageous for manufacturing aluminum alloy components due to its ability to produce parts with tight tolerances and excellent surface finishes.

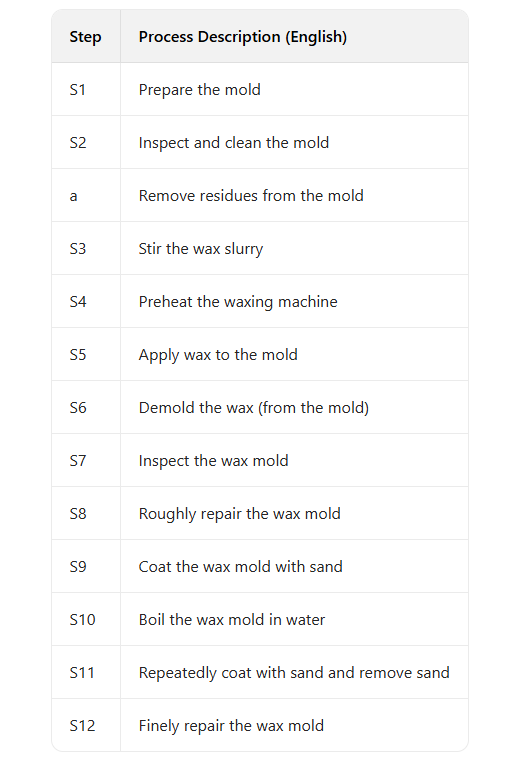

The investment casting process typically follows these steps:

1. Wax Pattern Creation: A precise wax replica of the desired part is produced using injection molding.

2. Assembly: Multiple wax patterns are assembled onto a central wax structure called a "tree."

3. Shell Building: The wax assembly is coated with ceramic material, layer by layer, until a durable shell is formed.

4. Dewaxing: The wax is melted and removed, leaving the ceramic mold ready for casting.

5. Casting: Molten aluminum is poured into the mold cavity.

6. Cooling and Finishing: After solidification, the ceramic shell is broken away, and the aluminum part undergoes finishing operations like machining or polishing.

Advantages of Investment Casting for Aluminum Components

Investment casting offers several benefits for producing aluminum parts:

- Complex Geometries: The process enables the creation of intricate designs that are challenging to achieve with other methods.

- Superior Surface Finish: Aluminum components produced through investment casting often require minimal post-processing due to their smooth surfaces.

- Dimensional Accuracy: Tight tolerances ensure that parts meet strict specifications without extensive machining.

- Material Versatility: Aluminum alloys used in investment casting provide excellent strength-to-weight ratios, corrosion resistance, and thermal conductivity.

Comparing Investment Casting with Other Aluminum Casting Methods

While investment casting is ideal for precision components, other aluminum casting techniques are better suited for specific applications. Below, we compare investment casting with aluminum sand casting, aluminum gravity casting, permanent mold aluminum casting, and low pressure aluminum die casting.

Aluminum sand casting involves creating a mold using sand and binding agents. This method is cost-effective and suitable for large parts or low-volume production. However, it lacks the dimensional precision and surface finish of investment casting. Sand casting is often used for structural components where aesthetics are less critical.

Aluminum gravity casting relies on gravity to pour molten metal into a mold. This technique is commonly used for medium-sized parts with simpler geometries. While it provides better dimensional accuracy than sand casting, it cannot match the intricate designs achievable through investment casting.

Permanent Mold Aluminum Casting

Permanent mold aluminum casting uses reusable metal molds to produce parts with consistent quality. This method offers faster production cycles and improved mechanical properties compared to sand casting but may be limited in terms of design complexity. Investment casting remains superior for highly detailed components.

Low Pressure Aluminum Die Casting

Low pressure aluminum die casting utilizes controlled pressure to inject molten aluminum into a mold. This process excels in producing high-strength parts with excellent surface finishes. However, it is more suited for high-volume production and may lack the flexibility of investment casting for complex designs.

Applications of Investment Casting in Aluminum Manufacturing

Investment casting is widely used across industries where precision and performance are paramount:

- Aerospace: Aluminum investment castings are employed in turbine blades, engine components, and structural parts due to their lightweight and durability.

- Automotive: High-performance aluminum alloy parts such as suspension components and transmission housings benefit from investment casting's accuracy.

- Medical Devices: The process enables the production of intricate surgical instruments and prosthetics.

- Industrial Equipment: Investment cast aluminum parts are used in pumps, valves, and other machinery requiring tight tolerances.

Optimizing Investment Casting for Aluminum Alloys

To achieve optimal results in aluminum investment casting, manufacturers focus on several key factors:

1. Material Selection: Choosing the right aluminum alloy based on desired mechanical properties and application requirements.

2. Design Considerations: Incorporating features like fillets and radii to improve mold filling and reduce stress concentrations.

3. Process Control: Monitoring temperature, cooling rates, and pouring techniques to ensure consistent quality.

4. Post-Casting Treatments: Applying heat treatments or surface coatings to enhance strength and corrosion resistance.

Future Trends in Aluminum Investment Casting

Advancements in technology continue to push the boundaries of investment casting:

- Additive Manufacturing Integration: 3D printing is revolutionizing wax pattern creation, enabling faster prototyping and more complex designs.

- Sustainability Initiatives: Efforts to recycle ceramic molds and reduce waste are making investment casting more environmentally friendly.

- Automation: Robotic systems are improving efficiency and precision in shell building and pouring processes.

Investment casting remains a cornerstone of precision manufacturing for aluminum components, offering unparalleled versatility and accuracy. While other methods like aluminum sand casting, aluminum gravity casting, permanent mold aluminum casting, and low pressure aluminum die casting have their merits, investment casting stands out for its ability to produce intricate designs with superior surface finishes. As industries continue to demand lightweight, high-performance parts, investment casting will play an increasingly vital role in shaping the future of aluminum manufacturing.

Dongrun Casting has 20000 square meters of facility houses and 200 production & test equipment, From quotation and tooling design to casting and finished machining, we can work with you at every stage. We serve a wide range of industries-from Fortune 500 corporations to small and midsize OEMs. Our products include Automotive&trucking, Electric Utility & Communications, Metering Systems, the Hydraulic Industry, Medical Devices, Lighting, Fuel and Gas Pressure, and Furniture parts.

More Details: www.dongruncasting.com