Aluminum Oxide Coating on Die Casting With New Technology

According to reports, high-end smartphones such as iPhones typically use a smooth aluminum oxide film treatment on the aluminum alloy cut casing. This treatment is carried out to improve the corrosion resistance and wear resistance of aluminum alloys, and to highlight the high-end feeling through coloring. But the existing problem is that cutting operations are time-consuming and require not only cutting machines, but also fixtures and drilling tools, which are costly.

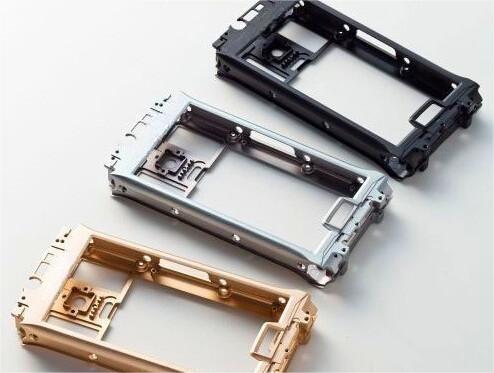

The aluminum die casting process utilizes molds for molding, resulting in shorter processing time and lower costs. Taking the case of a smartphone as an example, when using the cutting process, it takes more than 30 minutes to complete the cutting, and coupled with the finishing operation, it is estimated to take nearly an hour. The die-casting process only takes 20-30 seconds to form, and combined with the precision machining process, the operation can be completed in 10-20 minutes.

However, it is difficult to achieve smooth aluminum oxide film treatment in ordinary aluminum die-casting processes. The reason is that silicon was added to the raw material in order to improve its flowability and flow through all areas of the mold. Therefore, if you want to color aluminum die castings, they may lose their high-end feel after painting because they look like plastic.

According to the report, after developing aluminum alloys for die castings that contain almost no silicon, the company has achieved smooth aluminum oxide film treatment for aluminum die castings by improving mold and aluminum oxide film treatment conditions. The mechanical properties exhibited on the smartphone casing are similar to those of ordinary 6000 aluminum alloys. The tensile strength is about 180MPa, the Vickers strength is about 60Hv, and the elongation is close to 20%. Moreover, the minimum formable thickness is only 0.8mm.

At present, this process has been applied to earphone components and smartphone shells. In addition to digital appliances such as smartphones, audio devices, televisions, and digital cameras, white goods manufacturers such as refrigerators and car equipment manufacturers have also shown strong interest in this process.

ZheJiang Dongrun Casting Industry Co,.Ltd was built in 1995, We have been in the casting industry for more than 25 years. No matter what type of molding you need done, we are the right supplier for your jobs. Unlike other of our competition, we offer four types of castings.

Dongrun Casting have 20000 square meters facility houses and 200 production & test equipment, From quotation and tooling design to casting and finished machining, we can work with you at every stage. We serves wide range of industries-from Fortune 500 corporations to small and midsize OEMs. Our products includes:

❖ HVAC | ❖ Architectural parts |

Browse our online showroom to see what we can do for you. And then E-mail:dongrun@dongruncasting.com us your specifications or inquiries today