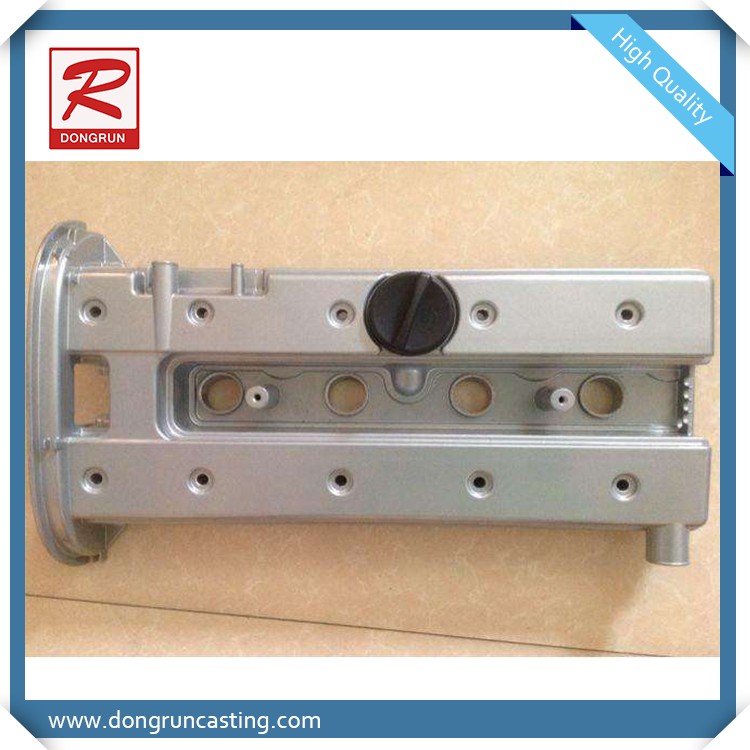

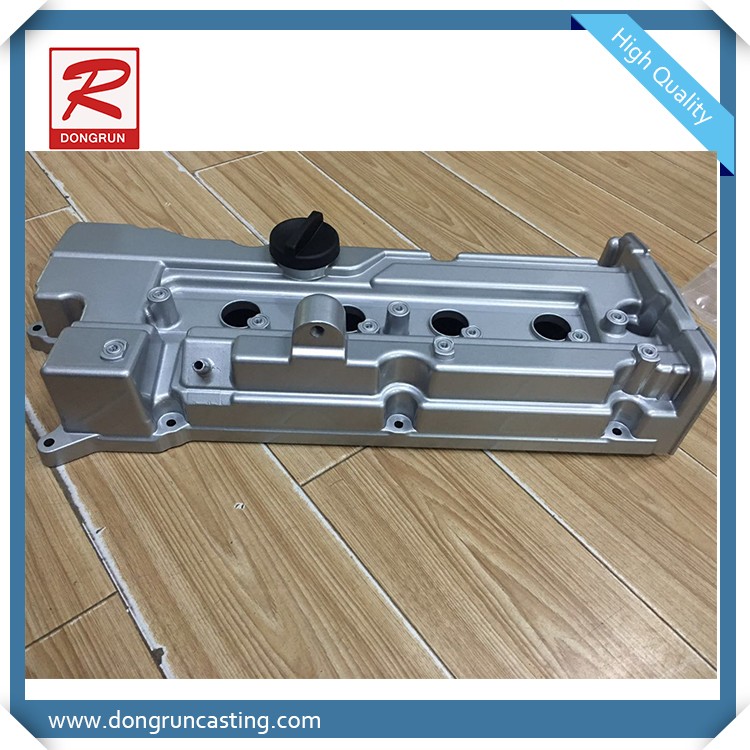

How to Make Cast Aluminum Valve Covers: A Guide to the Casting Process

Cast aluminum valve covers are essential components in modern engines, providing durability, heat resistance, and lightweight performance. The manufacturing of these valve covers involves advanced casting techniques, each offering unique advantages. In this blog, we’ll explore the casting processes commonly used and highlight how Dongrun Casting Industry Co., Ltd ensures quality and precision in every step of production.

Key Casting Processes for Aluminum Valve Covers

1. Sand Casting

Sand casting is one of the oldest and most versatile methods for producing cast aluminum valve covers. This process involves creating a mold from sand, into which molten aluminum is poured. Sand casting is ideal for prototypes and low-volume production due to its cost-effectiveness and ability to handle complex designs.

2. Gravity Casting

Gravity casting uses gravity to fill the mold with molten aluminum, resulting in denser and more structurally sound valve covers. This method is particularly suitable for medium-volume production and ensures excellent dimensional accuracy.

3. Permanent Mold Casting

In permanent mold casting, reusable steel or cast iron molds are used to produce high-quality aluminum valve covers. The process offers superior surface finishes and consistent results, making it a popular choice for high-performance applications.

4. High-Pressure Die Casting

High-pressure die casting involves injecting molten aluminum into a steel mold under high pressure. This method is ideal for large-scale production, delivering exceptionally precise and lightweight valve covers. It’s widely used in the automotive industry for its efficiency and cost-effectiveness.

Quality Control at Dongrun Casting Industry Co., Ltd.

As a leading Cast Aluminum Valve Covers factory and supplier, Dongrun Casting Industry Co., Ltd. has decades of experience in aluminum casting and machining. Our commitment to quality begins at the design stage and extends through every phase of production.

1. Material Selection and Inspection

We use premium-grade aluminum alloys, ensuring optimal strength and thermal properties. Incoming materials undergo rigorous testing to meet industry standards.

2. Advanced Casting Techniques

Whether it’s sand casting for intricate designs or high-pressure die casting for mass production, we leverage state-of-the-art equipment and expertise to deliver precision-engineered valve covers.

3. Dimensional Accuracy

Our quality control team performs detailed inspections using advanced metrology tools to ensure every valve cover meets exact specifications.

4. Machining Excellence

After casting, each valve cover undergoes meticulous machining to achieve tight tolerances and flawless finishes. Our CNC machining centers provide unparalleled accuracy and repeatability.

5. Final Testing

Before shipment, all products are subjected to rigorous testing for durability, leak resistance, and surface quality.

Why Choose Dongrun Casting Industry Co., Ltd.?

With a proven track record in aluminum casting, Dongrun Casting Industry Co., Ltd. is your trusted partner for high-quality cast aluminum valve covers. Our expertise spans multiple casting methods, allowing us to tailor solutions to your specific needs. From prototypes to large-scale production, we deliver products that exceed expectations.

Ready to collaborate with a reliable Cast Aluminum Valve Covers supplier? Contact Dongrun Casting Industry Co., Ltd. today to learn more about our capabilities!

By integrating cutting-edge technology with strict quality control measures, Dongrun Casting Industry Co., Ltd. continues to set the benchmark in the casting industry.

Dongrun Casting has 20000 square meters of facility houses and 200 production & test equipment, From quotation and tooling design to casting and finished machining, we can work with you at every stage. We serve a wide range of industries-from Fortune 500 corporations to small and midsize OEMs. Our products include Automotive&trucking, Electric Utility & Communications, Metering Systems, the Hydraulic Industry, Medical Devices, Lighting, Fuel and Gas Pressure, and Furniture parts.

More Details: www.dongruncasting.com