Sand casting process

The basic process of sand casting process has the following steps: mold production part, sand mixing stage, molding (core making) stage, smelting stage, pouring stage, cleaning stage and other steps. Sand casting process is a casting method in which sand is used as the main molding material to prepare a casting mold. Sand casting is the most traditional casting

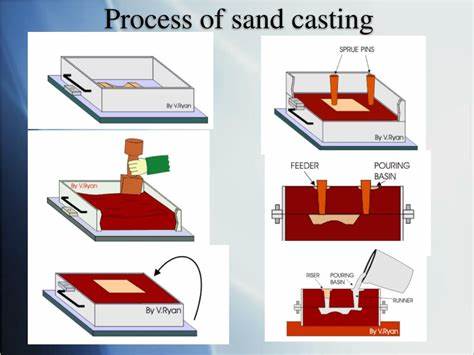

The main processes of sand casting are:

1. Mold production part: make molds according to the requirements of drawings. Generally, wooden molds can be used for single-piece production, plastic molds and metal molds can be made for mass production, and templates for large-scale castings can be made.

2. Sand mixing stage: According to the requirements of sand mold manufacturing and different types of castings, qualified molding sand is prepared for molding.

3. Modeling (core making) stage: including modeling (using sand to form the cavity of the casting), core making (forming the internal shape of the casting), and mold matching (putting the core into the cavity, and closing the upper and lower flasks together) ). Modeling is a key link in casting.

4. Smelting stage: prepare the chemical composition according to the required metal composition, select a suitable melting furnace to melt the alloy material, and form a qualified liquid metal liquid (including qualified components and qualified temperature)

5. Pouring stage: pour the qualified molten metal into the sand box equipped with the mold. The pouring stage is very dangerous, so special attention should be paid to it.

6. Cleaning stage: After the molten metal solidifies after pouring, remove the molding sand and knock out the gate and other accessories to form the required casting.

ZheJiang Dongrun Casting Industry Co,.Ltd was built in 1995, We have been in the casting industry for more than 25 years. No matter what type of molding you need done, we are the right supplier for your jobs. Unlike other of our competition, we offer four types of castings.

Dongrun Casting have 20000 square meters facility houses and 200 production & test equipment, From quotation and tooling design to casting and finished machining, we can work with you at every stage. We serves wide range of industries-from Fortune 500 corporations to small and midsize OEMs. Our products includes:

❖ HVAC | ❖ Architectural parts |

Browse our online showroom to see what we can do for you. And then E-mail:dongrun@dongruncasting.com us your specifications or inquiries today