Shell Mold Casting: A Comprehensive Guide to Precision Casting Techniques

Shell mold casting is an advanced metal casting technique that combines precision, efficiency, and versatility, making it a preferred choice for complex and high-quality parts. This article delves into the intricacies of shell mold casting, comparing it with other widely used methods such as aluminum casting, sand casting, gravity casting, and permanent mold casting. By understanding its advantages and applications, manufacturers can make informed decisions to optimize production processes and achieve superior results.

Introduction to Shell Mold Casting

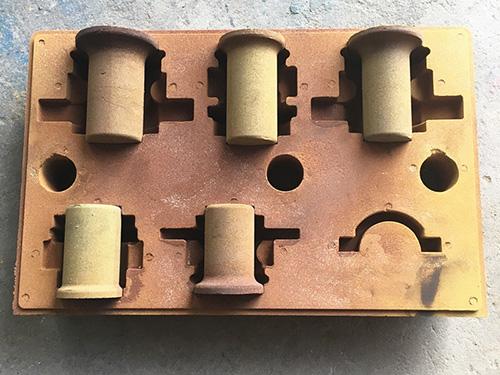

Shell mold casting is a specialized form of sand casting that utilizes a resin-coated sand to create a thin, hardened shell mold. This process is renowned for its ability to produce intricate designs with exceptional dimensional accuracy and surface finish. It is widely employed in industries such as automotive, aerospace, and machinery manufacturing, where precision and durability are critical.

The technique involves creating a mold by heating a metal pattern and coating it with resin-coated sand. Once the shell hardens, it is removed from the pattern and assembled to form a complete mold. Molten metal is then poured into the shell mold, solidifying into the desired shape. This process is particularly effective for producing small to medium-sized parts with intricate geometries.

Advantages of Shell Mold Casting

1. Superior Dimensional Accuracy

Shell mold casting offers higher precision compared to traditional sand casting methods. The rigid shell molds maintain their shape during the pouring process, ensuring tight tolerances and consistent dimensions.

2. Enhanced Surface Finish

Thanks to the smooth resin-coated sand used in the molds, shell mold casting delivers a superior surface finish that reduces the need for post-casting machining or polishing.

3. Versatility in Materials

This method supports a wide range of materials, including aluminum casting, iron, steel, and other alloys. Aluminum casting, in particular, benefits from shell mold casting due to its lightweight properties and excellent corrosion resistance.

4. Efficient Production Process

The thin shell molds require less material than traditional sand molds, reducing waste and improving efficiency. Additionally, the process allows for faster production cycles.

Shell Mold Casting vs. Other Casting Techniques

Sand Casting

While both methods use sand as the primary molding material, shell mold casting differs by utilizing resin-coated sand to create rigid molds. Sand casting is more cost-effective for large-scale production but lacks the precision and surface finish achieved through shell mold casting.

Gravity Casting

Gravity casting involves pouring molten metal into a mold using gravity rather than external force. While it is ideal for simple designs and thicker parts, it does not offer the intricate detailing or dimensional accuracy of shell mold casting.

Permanent Mold Casting

Permanent mold casting uses reusable molds made from metal or other durable materials. This method is well-suited for high-volume production but may struggle to replicate complex geometries compared to the flexibility of shell mold casting.

Applications of Shell Mold Casting

Shell mold casting is widely used across industries due to its ability to produce high-quality components with complex designs. Common applications include:

- Automotive Industry:Engine blocks, cylinder heads, and transmission components.

- Aerospace Sector:Precision turbine blades and structural components.

- Industrial Machinery:Gears, valves, and pump housings.

- Consumer Goods:Decorative hardware and custom parts.

Optimizing Shell Mold Casting for Aluminum Components

Aluminum casting is one of the most popular applications for shell mold casting due to aluminum's lightweight nature and excellent thermal conductivity. To maximize efficiency and quality:

1. Material Selection:Use high-purity aluminum alloys for better mechanical properties.

2. Design Optimization:Incorporate features such as fillets and draft angles to facilitate smooth flow of molten metal.

3. Temperature Control:Maintain precise temperature settings during pouring to prevent defects such as porosity or shrinkage.

4. Post-Casting Treatments:Employ heat treatment processes to enhance strength and durability.

Future Trends in Shell Mold Casting

As manufacturing technologies advance, shell mold casting continues to evolve with innovations such as:

- Automation:Robotic systems for mold assembly and pouring enhance precision and reduce labor costs.

- Additive Manufacturing Integration:Combining 3D printing with shell mold casting enables rapid prototyping and complex designs.

- Eco-Friendly Practices:Development of biodegradable resin coatings and recycled sand materials minimizes environmental impact.

Shell mold casting stands out as a versatile and efficient method for producing high-quality metal parts with intricate designs. By understanding its advantages and comparing it with alternative techniques like sand casting, gravity casting, and permanent mold casting, manufacturers can select the most suitable process for their specific needs. Whether working with aluminum casting or other materials, shell mold casting offers unparalleled precision and reliability that meet the demands of modern industries.

Dongrun Casting has 20000 square meters of facility houses and 200 production & test equipment, From quotation and tooling design to casting and finished machining, we can work with you at every stage. We serve a wide range of industries-from Fortune 500 corporations to small and midsize OEMs. Our products include Automotive&trucking, Electric Utility & Communications, Metering Systems, the Hydraulic Industry, Medical Devices, Lighting, Fuel and Gas Pressure, and Furniture parts.

More Details: www.dongruncasting.com