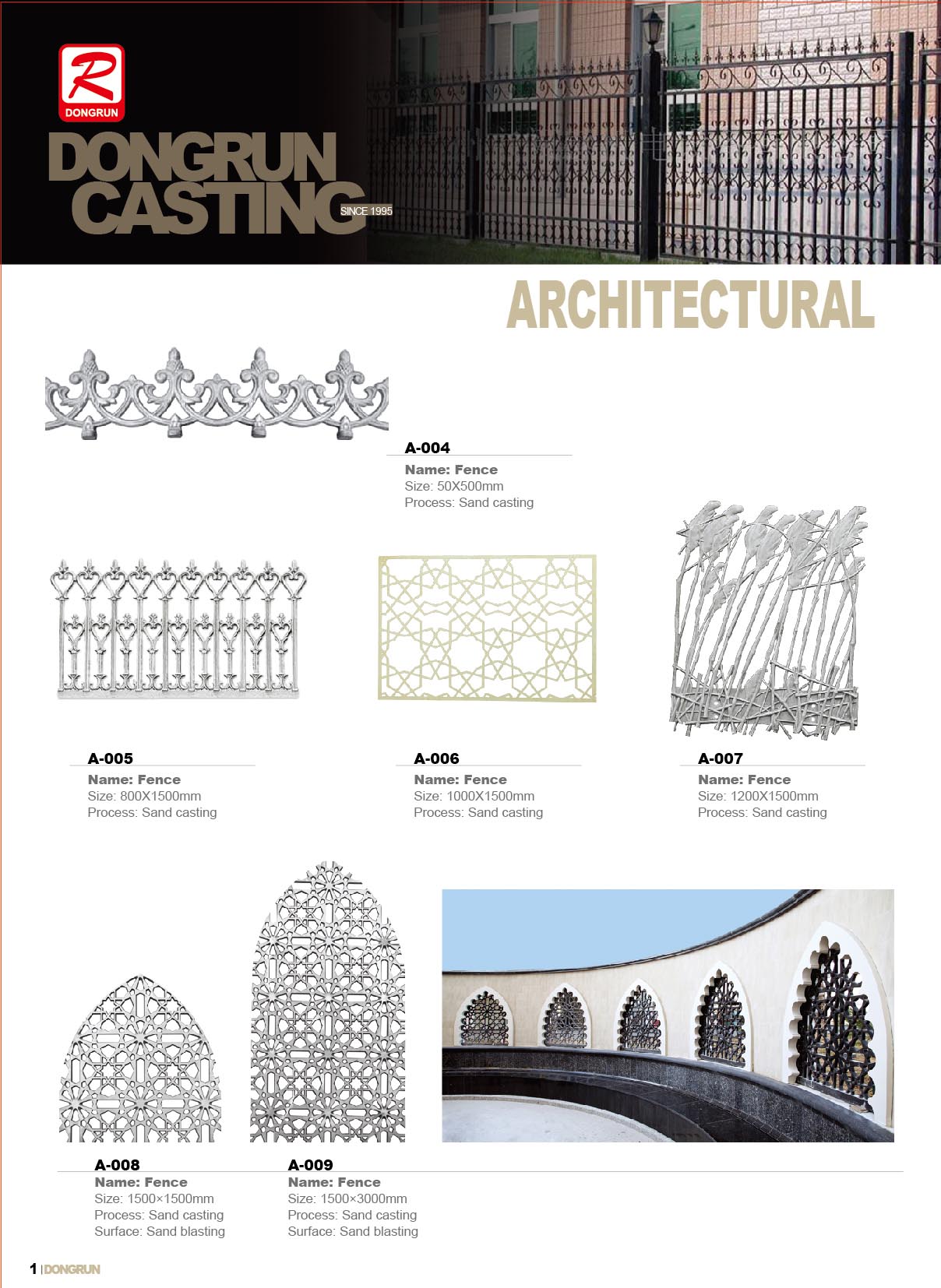

Product Description

Cast aluminum fence panels are decorated with rust removal, wear resistance, corrosion resistance and oxidation resistance, and meet the needs of people in terms of environmental protection, health and visual aesthetics. Therefore, cast aluminum fence panels have always been loved by the public, and the future trend will definitely replace cast iron fences and become the main material for buildings. Why are cast aluminum fence panels so popular? Are there any advantages of cast aluminum fence panels? Analyze the six advantages of cast aluminum fence panels:

1. Corrosion-resistant, maintenance-free, safe and environmentally friendly

Aluminum alloy has good mechanical properties and corrosion resistance under natural conditions, which can fully meet the requirements of anti-corrosion control as a protective material, and is more suitable for use in high-rise buildings. Long life, no maintenance, no rust pollution, safe and stable.

2. Good plasticity, many styles, scientific structure

Aluminum alloy has good hot extrusion performance, and can be made into various shapes of hollow and solid profiles according to the requirements of the best mechanical structure and appearance process.

3. Light texture, high strength, adapt to the times

The structural strength of aluminum platform gold is high, and it is only less than one-third of the quality of steel, which increases the overall load-bearing capacity of the building. Coupled with a good combination of toughness, weld-ability and other performance advantages, it is especially suitable for use in high-rise buildings.

4. Soft texture, beautiful color, highlight personality

Aluminum alloy's excellent surface treat-ability, good adhesion fastness and surface texture not only allow cast aluminum products to have a variety of surface treatment options, but also stable and durable, from the color and appearance of the guardrail products to meet personalized, diverse It has become possible to adapt to different aesthetic needs.

5. Fully welded, not loose, safe and stable

Full welding technology is used in the production of balcony guardrails, so that each contact of the horizontal bar and the vertical bar is integrated, which eliminates the hidden dangers of unsafe caused by the loosening of the fixed connection and improves the overall impact resistance of the guardrail.

6. Standardization, convenient installation

According to the needs of the domestic market and engineering installation habits, a number of products suitable for different styles and engineering conditions have been formulated and standardized production has been carried out. While satisfying rapid mass production, it can also provide quality for the entire process of production, transportation and installation.

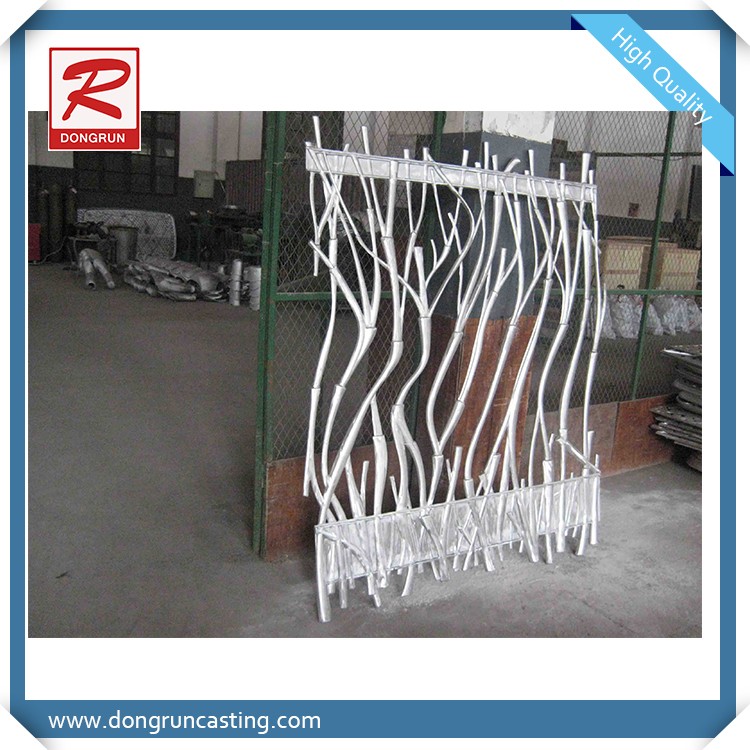

How to do cast aluminum fence panels

In our factory, we are doing cast aluminum fence panels by sand casting process and die casting process, welcome to send us your design, we can offer you good quality.

Dongrun is the professional manufacturer of Casting products which lies in Yongkang city,Zhejiang Province . Our factory was built in 1995, we have been in the casting industry more than 25 years. And we are experienced to deal with all different kinds of casting products . We have our good team, our engineers can offer exact price list in 48 hours after we get your drawings or samples.

Just one point: We are only special in CASTING & MACHINING

In short: We are such kind one factory that supply casting products according to your samples or drawings

Factory Cabability

| Material | 1. Sand casting&Gravity casting&Low pressure die casting: |

| Service | Sand casting, Gravity casting, high pressure die casting,low pressure die casting and CNC Machining casting. |

Equipment of Casting | 1. High pressure die casting machining:125T/180T/250T/280T/500T/800T/1250T 2. Gravity casting machine: 7 production lines 3. Low pressure die casting machining: 1 production line 4. Sand casting machine: 6 production lines 5. Degassing equipment and opportunities to refine the material 6. Machining: 9 Sets CNC Machines; 5 sets Milling machines; 3 setsTurning machines; 20 sets drill and tap machines |

| Testing Facility | Spectrometer, Tensile test device, Hardness test device, CMM, X-Ray, Leaking test device |

Precision Machining | CNC turning, Milling, Drilling, Grinding, Cutting, Reaming and Threading |

| Finished | Polishing, Sand blasting, Heat treatment, Painting, Powder coating, Anodizing, Electroplating, Chrome plating, Mirror polishing. |

| Products | All kinds of Cast aluminum productions: Including Vehicle industry,Medical device industry, Marine industry, Lighting industry,Oil&Gas Transporttation industry, Electric Utility & Communication Industries, Architectural industry and Furniture industry so on |

Production Images

|  |  |

Company Projects

From Casting to Surface Finished, One-stop Solutions for your designs

Packing & Shipping

Casting parts are very heavy, package must be strong. Our package material is wooden crate which is Fumigation free.

And we can pack productions as customers' requirements

FAQ

Q1. Are you trading company or manufacturer

We are factory, We are only doing cast aluminum and machining more than 20years, we have much experience in this industry. If you find some "factory" can do kinds of material castings(steel, iron,stainless,cooper.......), we are sure they are trading company. If you have other material castings to do, we can introduce for you free. It is our pleasure that we can help you.

Q2. How to get quotation from your factory?

We need a 3D CAD solid model to prepare a First Quote interactive quote. All of the Firstcut processes are dependent on good 3D CAD solid models. Two-dimensional (2D) drawings are not adequate for quoting or making parts.

We can accept native SolidWorks (.sldprt) or ProE (.prt) files as well as solid 3D CAD models from other CAD systems output in IGES (.igs), STEP (.stp), ACIS (.sat) or Parasolid (.x_t or .x_b) format.

Q3. When can I get the price?

We usually quote within 48 hours after we get your inquiry. If you are very urgent, please call us or tell us in your email so that we will regard your inquiry priority.

Q4. How about your lead time?

1): Toolings &Samples

Sand Casting will take 15 to 30 days after receiving your advance payment.

Gravity casting, low pressure die casting, high pressure die casting will take 30 to 60days after receiving your advance payment.

2) Mass production

The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings. We can build drawings for you after we get your samples too.

Q6. What is your sample policy?

We can supply 1pcs sample free (value under USD15/PCS) after we finish as your drawings, but the customers have to pay the freight cost. If you need more samples, you have to pay the samples cost.

Q7. Can we use your current tooling? Or can we get samples which are shown on your website?

No, we can't do it.

We only accept OEM orders and do casting parts as your drawings or samples. We can't sell any production or design to any third body. We can't show any photos on website without our clients' allowance. We signed NDA with all clients, all tooling and drawings belong our clients. We only use the tooling to make productions for one client. The client can take way the tooling any time after tooling cost.

Q8. Do you test all your goods before delivery?

Yes, we have 100% test before delivery

Q9: How do you make our business long-term and good relationship?

We keep good quality and competitive price to ensure our customers benefit ;

We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.