Exploring Anodized Finishes in Aluminum Casting: Enhancing Durability and Aesthetics

In the world of aluminum casting, surface finishing plays a crucial role in determining the durability, aesthetics, and performance of the final product. Among the various finishing techniques, anodized finishes stand out as a preferred choice due to their ability to enhance corrosion resistance, wear resistance, and visual appeal. This article delves into the significance of anodized finishes in aluminum casting, while exploring key casting methods such as sand casting, gravity casting, permanent mold casting, and low-pressure die casting. Additionally, we will discuss related processes like black oxide, anodizing, and hard anodizing, shedding light on their applications and benefits.

Anodized Finishes: A Game-Changer in Aluminum Casting

Anodizing is an electrochemical process that increases the natural oxide layer on the surface of aluminum parts. This controlled oxidation not only improves corrosion resistance but also provides a durable and decorative finish. Anodized finishes are particularly valued in industries such as aerospace, automotive, electronics, and consumer goods, where both functionality and aesthetics are critical.

The anodizing process involves three main types: standard anodizing (commonly referred to as "anodizing"), black anodizing (or black oxide), and hard anodizing. Each type offers unique benefits:

Standard Anodizing: Enhances corrosion resistance and allows for color customization.

Black Anodizing (Black Oxide): Provides a sleek, matte black finish with excellent durability.

Hard Anodizing: Creates a thicker oxide layer for superior wear resistance, often used in heavy-duty applications.

Aluminum Casting Methods and Their Compatibility with Anodized Finishes

To achieve high-quality anodized finishes, the aluminum casting method plays a pivotal role. Let’s examine some common casting techniques and their suitability for anodizing:

Sand Casting

Sand casting is one of the oldest and most versatile aluminum casting methods. It involves pouring molten aluminum into a sand mold to create complex shapes. While sand casting is cost-effective for low-volume production, the surface finish often requires additional machining or polishing to prepare it for anodizing. Anodized finishes on sand-cast parts can enhance their corrosion resistance and improve their visual appeal.

Gravity Casting

Gravity casting, also known as permanent mold casting, uses gravity to pour molten aluminum into a reusable mold. This method produces parts with better dimensional accuracy and smoother surfaces compared to sand casting. The improved surface quality makes gravity-cast parts ideal candidates for anodizing, ensuring a uniform and attractive finish.

Permanent Mold Casting

Permanent mold casting is similar to gravity casting but may involve additional techniques such as vacuum assistance to improve mold filling. The dense microstructure achieved through this process enhances the mechanical properties of the castings. When paired with anodized finishes, permanent mold castings offer exceptional durability and resistance to environmental factors.

Low-Pressure Die Casting

Low-pressure die casting involves applying controlled pressure to fill the mold with molten aluminum. This results in castings with excellent surface finishes and minimal porosity—key factors for achieving high-quality anodized coatings. Low-pressure die casting is commonly used for manufacturing automotive components, where both performance and aesthetics are paramount.

The Importance of Alloy Selection in Anodizing

Not all aluminum alloys are created equal when it comes to anodizing. The alloy composition significantly impacts the quality of the anodized finish. For example:

- High-Silicon Alloys: Commonly used in sand casting, these alloys may produce a darker or uneven anodized layer due to the presence of silicon.

- Low-Silicon Alloys: Preferred for gravity casting and permanent mold casting, these alloys yield brighter and more consistent anodized finishes.

- Specialty Alloys: Certain alloys are specifically designed for applications requiring hard anodizing, offering superior wear resistance.

Choosing the right alloy is critical for achieving the desired balance between mechanical properties and surface finish quality.

Black Oxide vs. Anodizing: Understanding the Differences

While black oxide and black anodizing are often used interchangeably, they are distinct processes with different applications:

- Black Oxide: A chemical conversion coating applied to ferrous metals (and sometimes aluminum), black oxide provides a matte black appearance but offers limited corrosion resistance compared to anodizing.

- Black Anodizing: A subset of the anodizing process, black anodizing creates a durable oxide layer that is both decorative and protective. It is widely used for consumer electronics, automotive components, and architectural applications.

Both processes have their place in manufacturing but serve different purposes based on performance requirements.

Hard Anodizing: Pushing the Limits of Performance

Hard anodizing takes the standard anodizing process to the next level by creating a thicker and harder oxide layer. This process is ideal for applications requiring exceptional wear resistance, such as hydraulic components, aerospace parts, and industrial machinery.

Key benefits of hard anodizing include:

- Enhanced abrasion resistance

- Improved thermal insulation

- Increased hardness (up to 60 Rockwell C)

- Excellent adhesion properties for additional coatings

When combined with advanced aluminum casting methods like low-pressure die casting or permanent mold casting, hard-anodized parts deliver unparalleled performance in demanding environments.

Applications of Anodized Aluminum Castings

Anodized finishes have become indispensable across various industries due to their versatility and performance benefits. Common applications include:

- Aerospace: Lightweight yet durable components with superior corrosion resistance.

- Automotive: Decorative trims, engine parts, and structural components with enhanced aesthetics.

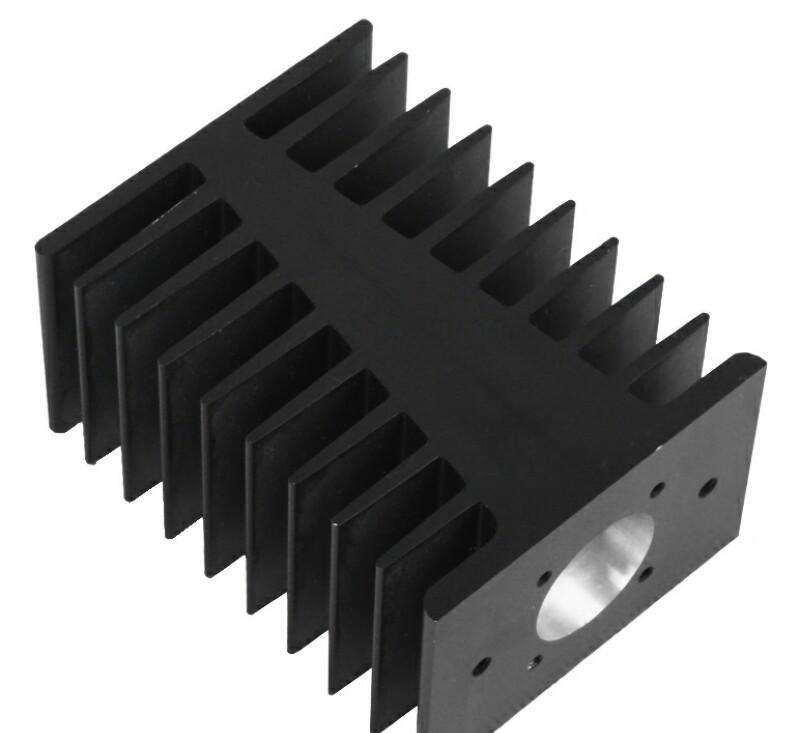

- Electronics: Heat sinks and enclosures with improved thermal conductivity and scratch resistance.

- Architecture: Facades and structural elements with long-lasting color stability.

The combination of advanced aluminum casting techniques and anodized finishes ensures that these products meet stringent industry standards while maintaining an attractive appearance.

Anodized finishes are a cornerstone of modern aluminum casting, offering a winning combination of durability, aesthetics, and functionality. Whether through sand casting for complex geometries or low-pressure die casting for precision components, the choice of casting method significantly influences the quality of the final product. By understanding the nuances of processes like black oxide, standard anodizing, and hard anodizing, manufacturers can tailor their solutions to meet specific application requirements.

As industries continue to demand lightweight yet robust materials, the synergy between aluminum casting and anodized finishes will remain a key driver of innovation. With careful alloy selection, advanced casting techniques, and expertise in surface finishing, manufacturers can unlock new possibilities in design and performance—pushing the boundaries of what anodized aluminum castings can achieve.

Product Pictures

|  |  |