Comprehensive Guide to the Electrophoretic Painting Process (E-Coating)

The Electrophoretic Painting Process (E-Coat) is a highly efficient and versatile method for applying coatings to metal parts, combining aspects of both plating and painting. This process has become an essential step in a variety of industries, particularly in automotive, aerospace, and manufacturing, where superior surface protection and uniform coating are critical. This article delves into the details of the E-coating process, its preparation steps, curing methods, and advantages, while also exploring its relevance to aluminum casting techniques such as sand casting, gravity die casting, permanent mold casting, low pressure die casting, and high pressure die casting.

What is Electrophoretic Painting (E-Coating) ?

The E-coating process involves immersing a metal part into a water-based solution containing a paint emulsion. By applying an electric voltage to the part, the paint particles condense and adhere uniformly to the surface. This method allows for precise control over coating thickness, as the applied voltage determines the amount of material deposited. A key advantage of E-coating is its ability to coat both the exterior and interior surfaces of metal components, even in complex geometries where traditional painting methods may fail.

This process is often referred to as Cataphoresis Coating or Electrophoresis Coating, highlighting its reliance on electrochemical principles. The result is a durable, even coating that provides excellent corrosion resistance and aesthetic appeal.

E-Coating Process Steps

The E-coat process shares similarities with plating in terms of surface preparation but introduces unique steps for applying and curing the coating. Below is a detailed breakdown of the process:

Cleaning

The first step involves cleaning the metal surface to remove contaminants such as dirt, oil, and grease. Typically, an alkaline cleaner is used, although the choice of cleaning agent depends on the substrate material. Proper cleaning is crucial to ensure strong adhesion of the coating.

Rinsing

After cleaning, the part is rinsed with water to remove any residual cleaning agents or debris.

Acid Etching

The next step includes acid etching, which prepares the metal surface by removing oxides and creating a slightly roughened texture for better coating adhesion.

Rinsing

A second rinse follows acid etching to eliminate any remaining acidic residues.

Wetting Agent Dip

Some manufacturers recommend a wetting agent dip just before the part enters the E-coat tank. This step minimizes bubble formation on the surface of the part, ensuring uniform deposition of the coating. Bubbles can lead to defects in the final finish.

E-Coat Application

The part is immersed in the E-coat tank containing a water-based paint emulsion. An electric voltage is applied, causing paint particles to migrate and deposit onto the metal surface. The thickness of the coating is self-limiting due to the insulating nature of the deposited layer, which prevents over-coating in high-voltage areas.

E-Coat Rinsing and Recovery

After coating, the part moves to a rinse tank to remove excess paint emulsion. The rinse solution is filtered through an ultrafiltration unit that separates paint particles from the carrier liquid. The recovered paint is returned to the E-coat tank, making this process highly efficient with minimal waste.

DI Rinsing

Deionized (DI) water rinsing ensures that no contaminants remain before curing.

Curing

The final step involves curing the E-coat by heating it in an oven. The curing temperature and time depend on the type of paint chemistry used (e.g., epoxy or acrylic). For example, an acrylic-urethane E-coat may require curing at 320°F for 20 minutes. Curing can be achieved using convection ovens, infrared ovens, or a combination of both, depending on part geometry and size.

Advantages of E-Coating in Aluminum Casting Applications

Aluminum castings are widely used in industries such as automotive and aerospace due to their lightweight properties and excellent strength-to-weight ratio. Common aluminum casting methods include sand casting, gravity die casting, permanent mold casting, low pressure die casting, and high pressure die casting. These processes produce components with varying levels of complexity and surface finishes.

E-coating offers several advantages when applied to aluminum cast parts:

Uniform Coating:

The ability to coat both internal and external surfaces ensures complete coverage, even in parts with intricate geometries produced by sand casting or permanent mold casting.

Corrosion Resistance:

Aluminum castings benefit from enhanced corrosion protection through E-coating, making them suitable for harsh environments.

Aesthetic Appeal:

The smooth finish provided by E-coating enhances the appearance of aluminum components used in visible applications.

Durability:

The cured coating provides excellent resistance to wear and chipping, extending the lifespan of aluminum parts.

Eco-Friendly Process:

The ultrafiltration system recycles unused paint emulsion, reducing waste and environmental impact.

Curing Methods for E-Coated Parts

Curing is a critical step in achieving optimal coating properties such as hardness, adhesion, and durability. The choice of curing method depends on part size, geometry, and material:

Infrared Curing

Infrared (IR) curing uses radiant heat to cure the coating. This method is ideal for simple geometries where line-of-sight heating can effectively reach all surfaces. IR curing is energy-efficient and reduces overall cycle time.

Convection Curing

Convection ovens use circulating hot air to cure coatings uniformly across complex geometries. This method ensures that all areas of a part are properly cured, including those hidden from direct IR radiation.

Combined Curing

For parts with mixed geometries, a combination of infrared and convection curing may be employed to achieve complete curing efficiently.

Applications of E-Coating in Aluminum Casting

- E-coating has found extensive use across various industries due to its compatibility with aluminum castings produced by different methods:

- Automotive Industry:

Aluminum components such as engine blocks (produced by high pressure die casting) and suspension parts (produced by gravity die casting) benefit from E-coating for improved durability and corrosion resistance.

- Aerospace Industry:

Lightweight aluminum parts produced by sand casting or low pressure die casting are often E-coated for enhanced performance under extreme conditions.

- Consumer Goods:

Aluminum housings for electronics or appliances are frequently E-coated for aesthetic appeal and longevity.

The Electrophoretic Painting Process (E-Coat) is a cutting-edge solution for applying durable, uniform coatings to metal parts. Its ability to coat complex geometries, reduce waste through efficient recovery systems, and provide superior corrosion resistance makes it an ideal choice for aluminum castings produced via methods like sand casting, gravity die casting, permanent mold casting, low pressure die casting, and high pressure die casting.

Whether referred to as Cataphoresis Coating, Electrophoresis Coating, or simply E-Coating, this technology continues to play a pivotal role in modern manufacturing processes. By combining proper preparation steps with advanced curing techniques, manufacturers can achieve high-quality finishes that meet stringent industrial standards while maintaining eco-friendly practices.

For industries seeking reliable surface protection for aluminum components, E-coating remains an invaluable tool in ensuring both performance and aesthetics.

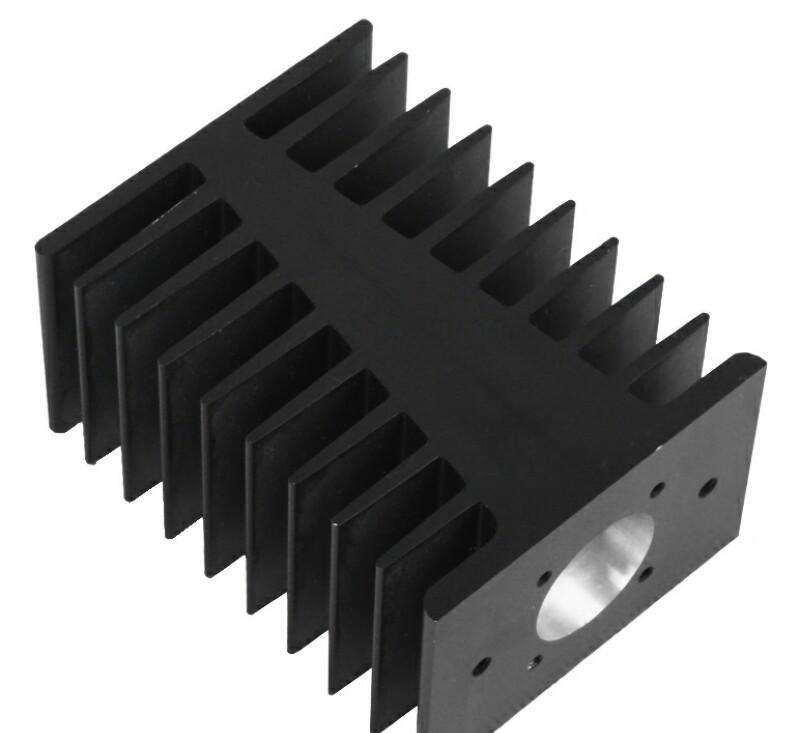

Product Pictures

|  |  |