Product Description

Zhejiang Dongrun Casting Industry Co,.Ltd supply the most comprehensive range of bellhousings in China meeting all worldwide standards such as VDMA, NEMA and ATEX.

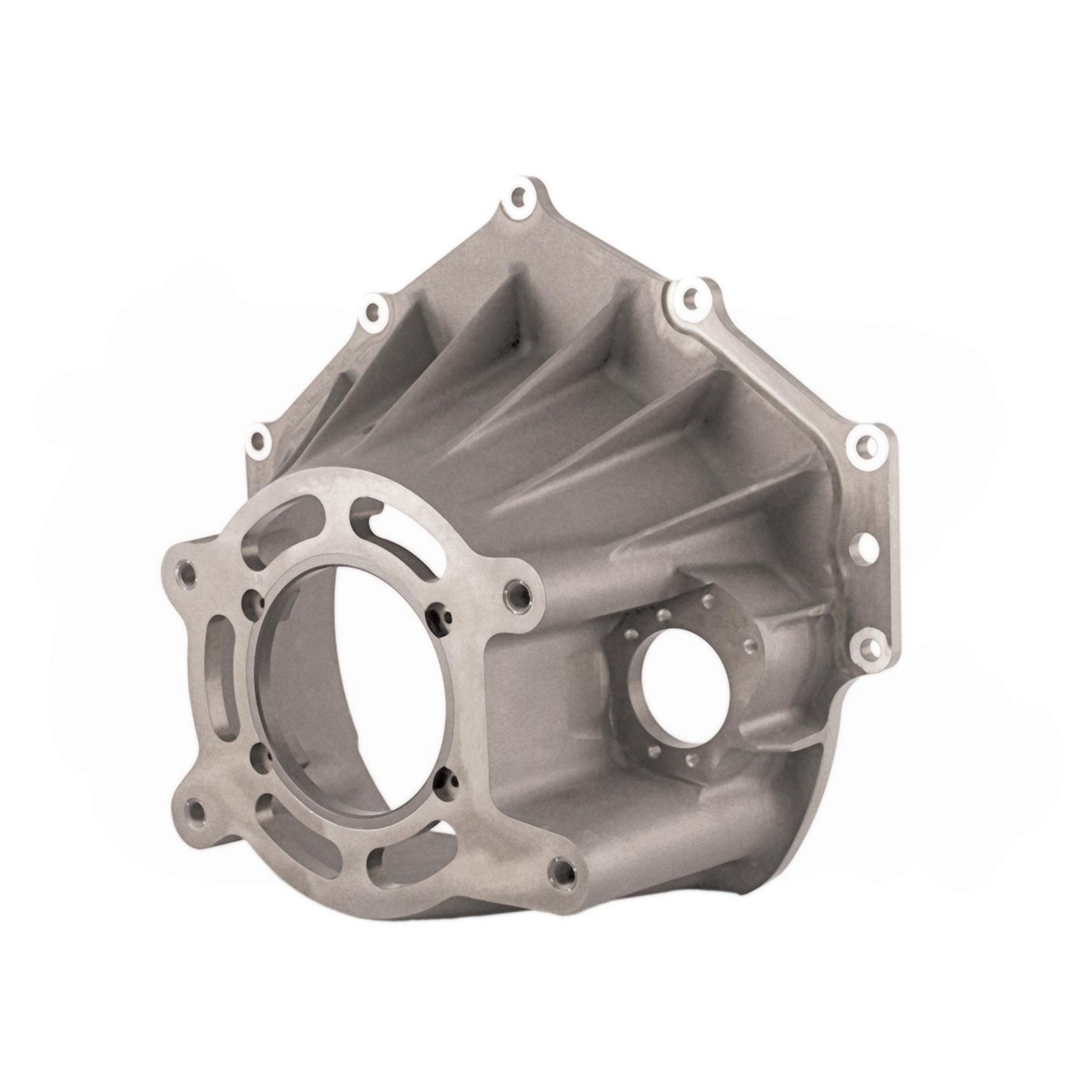

Bell housings are the mechanical elements used to connect an electric motor equipped with standard flange to a hydraulic pump, thus forming the pump/motor unit. The bell housings of this range allow to establish a perfect assembly between electrical motors with standard flange up to 270 kW and the majority of the hydraulic pumps available on the world market.

They are produced in aluminium alloy and are divided into two categories:

Single piece bell housings

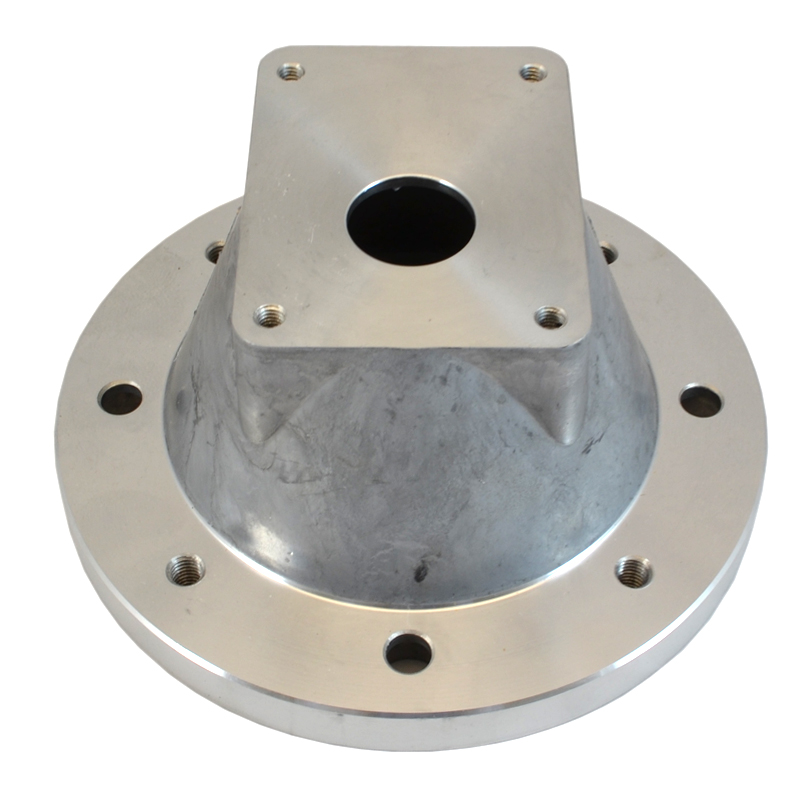

Composite Bell housings

Base Bell housing + flange

Base Bell housing + distance ring + flange

Materials and Material Properties:

Bell housings: Aluminium alloy for die casting process and sand casting process

Centering rings: Cut and zinc-plated sheet metal

Working temperature:-30°C to +80°C

On request, all our bell housings can be supplied with specific coating or surface treatment to make them also fully suitable under rough circumstances.

Available in aluminium, for general industrial power transmission applications, an additional range of noise reduction equipment exists for noise and vibration sensitive applications.

Bellhousings made from cast iron and cast aluminum and a range of exotic materials, units specifically designed for the most aggressive of environments.

A complete range of equipment also exists to allow the connection of diesel, petrol and air motors to any driven component.

Drive line harmony - achieve the best results to transmit mechanical power from A to B, transmit mechanical power from the driver to the driven.

Wide range of bellhousings, in large numbers kept in stock for prompt delivery.

Factory Cabability

General Products Application/Service Area | Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system. E.g. Engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve , valve housing ,Fitting , flange, wheel, flywheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc. |

| Service | Sand casting, Gravity casting, high pressure die casting,low pressure die casting and CNC Machining casting. |

Equipment of Casting | 1. High pressure die casting machining:125T/180T/250T/280T/500T/800T/1250T 2. Gravity casting machine: 7 production lines 3. Low pressure die casting machining: 1 production line 4. Sand casting machine: 6 production lines 5. Degassing equipment and opportunities to refine the material 6. Machining: 9 Sets CNC Machines; 5 sets Milling machines; 3 setsTurning machines; 20 sets drill and tap machines |

| Testing Facility | Spectrometer, Tensile test device, Hardness test device, CMM, X-Ray, Leaking test device |

Precision Machining | CNC turning, Milling, Drilling, Grinding, Cutting, Reaming and Threading |

| Finished | Polishing, Sand blasting, Heat treatment, Painting, Powder coating, Anodizing, Electroplating, Chrome plating, Mirror polishing. Machining surfce Ra0.8-Ra1.6 Machining Tolerance +/-0.025 |

| Lead Time | 45days for bell housing on a transmission |

Production Images

Affordable! High quality! Custom-made!

|  |  |

(Pictures for reference only, before quote, drawing is requested)

Send us your drawing, you will have the solutions!

Why Choose Us

❖ More than 25 years in castings and machining process; so we have much experience for your projects.

❖ Passed ISO9001 : 2015 & TS16949 : 2009

❖ Have four casting types in our factory; you can find the four process in one factory, save cost for your company

❖ From Casting to Finished surface, Owned casting, polishing and plating workshops, one-stop, We can offer Good quality and strict delivery time.

❖ With samples and order: We can offer dimension report, Chemical composition and Mechanical properties

❖ Control material with spectral and thermal analysis equipment (density and processing)

❖ Spectral analysis of raw material and liquid melt, batch before casting.

❖ Transportation Advantage:

A) Near Sea Port and Air Port-Ningbo Sea Port and Yiwu Airport or Hangzhou Airport;

B ) From Shanghai to our factory by Fast train directly, takes two and half hours; From Hangzhou to our factory, only takes one hour