Aluminum Grating: A Lightweight and Durable Solution

Grating is a type of flooring that is commonly used in industrial, commercial, and residential settings. It is made up of a series of parallel bars or crossbars that are welded or locked together to form a grid-like structure. Grating provides a slip-resistant surface that allows for the passage of air, light, and fluids. It is also used for drainage, ventilation, and safety purposes.

Aluminum grating is a popular choice for many applications due to its lightweight, durability, and corrosion resistance. In this blog post, we will explore the benefits of aluminum grating and why it is an excellent choice for your next project.

Lightweight

One of the most significant advantages of aluminum grating is its lightweight. Aluminum is a low-density metal that weighs approximately one-third of steel. This makes it easy to handle and transport, which can save time and money on installation costs. The lightweight nature of aluminum grating also makes it an ideal choice for applications where weight is a concern, such as in aerospace or marine industries.

Durable

Aluminum grating is also incredibly durable. It has a high strength-to-weight ratio, which means it can withstand heavy loads without bending or breaking. Aluminum grating is also resistant to corrosion, which makes it an excellent choice for outdoor applications or environments with high levels of moisture or chemicals.

Easy to Install

Another benefit of aluminum grating is that it is easy to install. The lightweight nature of aluminum grating means that it can be easily lifted and maneuvered into place. Additionally, aluminum grating can be cut to size on-site using standard tools, which makes installation quick and straightforward.

Low Maintenance

Aluminum grating requires minimal maintenance. It does not require painting or coating, and it is resistant to rust and corrosion. This means that aluminum grating can last for many years without needing repairs or replacement.

Versatile

Aluminum grating is a versatile material that can be used in a variety of applications. It is commonly used in industrial settings, such as walkways, platforms, and stair treads. It is also used in commercial and residential settings, such as balconies, decks, and pool areas. Aluminum grating can be customized to meet specific design requirements, such as size, shape, and color.

Cost-Effective

Aluminum grating is a cost-effective solution compared to other materials such as steel or fiberglass. Although the initial cost of aluminum grating may be higher than other materials, the long-term benefits such as low maintenance and durability make it a cost-effective choice in the long run.

Aluminum grating is an excellent choice for many applications due to its lightweight, durability, and corrosion resistance. It is easy to install, requires minimal maintenance, and is cost-effective in the long run. If you are looking for a reliable and versatile flooring solution, consider aluminum grating for your next project.

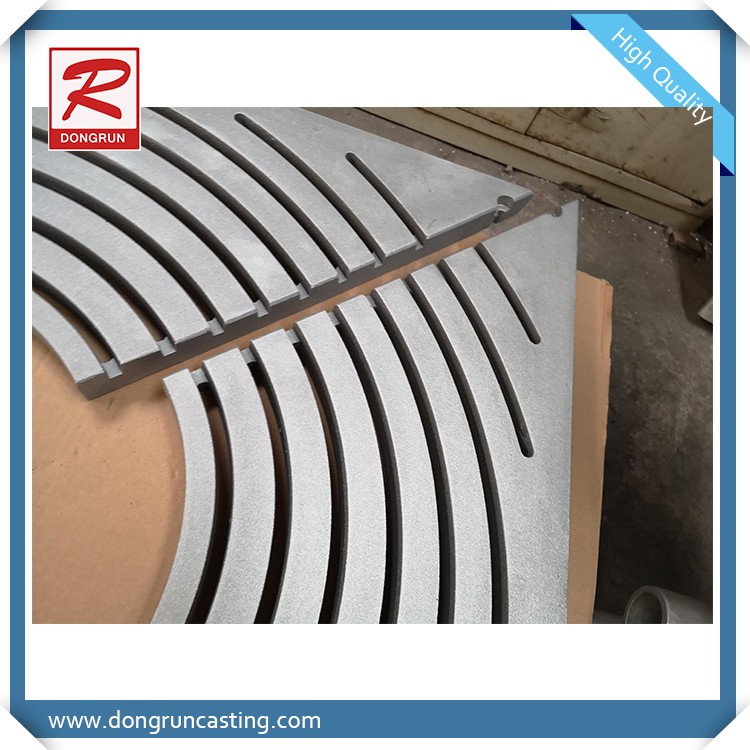

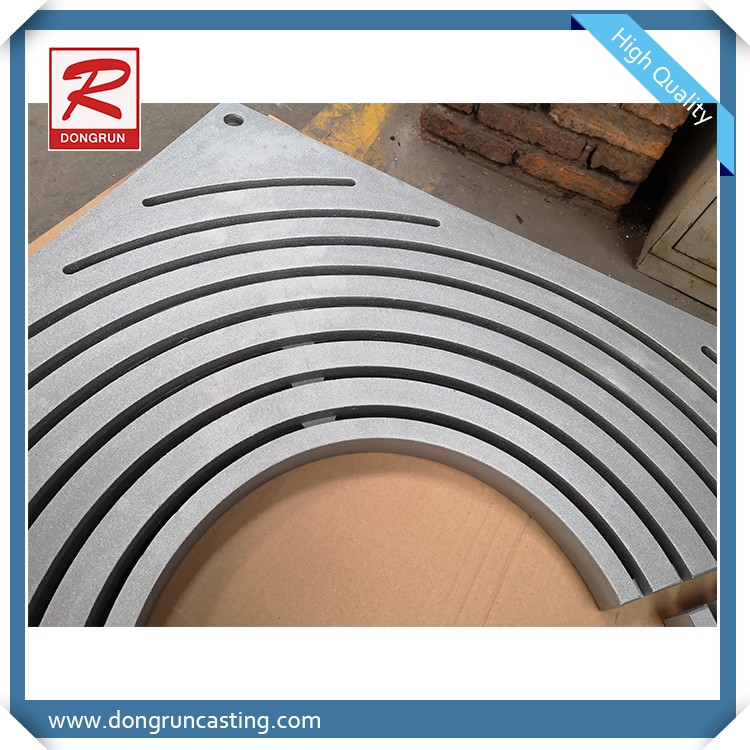

Production Images

|  |  |

Company Equipment

From Casting to Machining, One-stop Solutions for your designs

Packing & Shipping

Casting parts are very heavy, package must be strong. Our package material is wooden crate which is Fumigation free.

And we can pack productions as customers' requirements

Why Choose Us

❖ More than 25 years in castings and machining process; so we have much experience for your projects.

❖ Passed ISO9001 : 2015 & TS16949 : 2009

❖ Have four casting types in our factory; you can find the four process in one factory, save cost for your company

❖ From Casting to Finished surface, Owned casting, polishing and plating workshops, one-stop, We can offer Good quality and strict delivery time.

❖ With samples and order: We can offer dimension report, Chemical composition and Mechanical properties

❖ Control material with spectral and thermal analysis equipment (density and processing)

❖ Spectral analysis of raw material and liquid melt, batch before casting.

❖ Transportation Advantage:

A) Near Sea Port and Air Port-Ningbo Sea Port and Yiwu Airport or Hangzhou Airport;

B ) From Shanghai to our factory by Fast train directly, takes two and half hours; From Hangzhou to our factory, only takes one hour

FAQ

Q1. Are you trading company or manufacturer

We are factory, We are only doing cast aluminum and machining more than 20years, we have much experience in this industry. If you find some "factory" can do kinds of material castings(steel, iron,stainless,cooper.......), we are sure they are trading company. If you have other material castings to do, we can introduce for you free. It is our pleasure that we can help you.

Q2. How to get quotation from your factory?

We need a 3D CAD solid model to prepare a First Quote interactive quote. All of the Firstcut processes are dependent on good 3D CAD solid models. Two-dimensional (2D) drawings are not adequate for quoting or making parts.

We can accept native SolidWorks (.sldprt) or ProE (.prt) files as well as solid 3D CAD models from other CAD systems output in IGES (.igs), STEP (.stp), ACIS (.sat) or Parasolid (.x_t or .x_b) format.

Q3. When can I get the price?

We usually quote within 48 hours after we get your inquiry. If you are very urgent, please call us or tell us in your email so that we will regard your inquiry priority.

Q4. How about your lead time?

1): Toolings &Samples

Sand Casting will take 15 to 30 days after receiving your advance payment.

Gravity casting, low pressure die casting, high pressure die casting will take 30 to 60days after receiving your advance payment.

2) Mass production

The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings. We can build drawings for you after we get your samples too.

Q6. What is your sample policy?

We can supply 1pcs sample free (value under USD15/PCS) after we finish as your drawings, but the customers have to pay the freight cost. If you need more samples, you have to pay the samples cost.

Q7. Can we use your current tooling? Or can we get samples which are shown on your website?

No, we can't do it.

We only accept OEM orders and do casting parts as your drawings or samples. We can't sell any production or design to any third body. We can't show any photos on website without our clients' allowance. We signed NDA with all clients, all tooling and drawings belong our clients. We only use the tooling to make productions for one client. The client can take way the tooling any time after tooling cost.

Q8. Do you test all your goods before delivery?

Yes, we have 100% test before delivery

Q9: How do you make our business long-term and good relationship?

We keep good quality and competitive price to ensure our customers benefit ;

We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.