Extension Housing: A Comprehensive Guide to Aluminum Casting in Automotive Applications

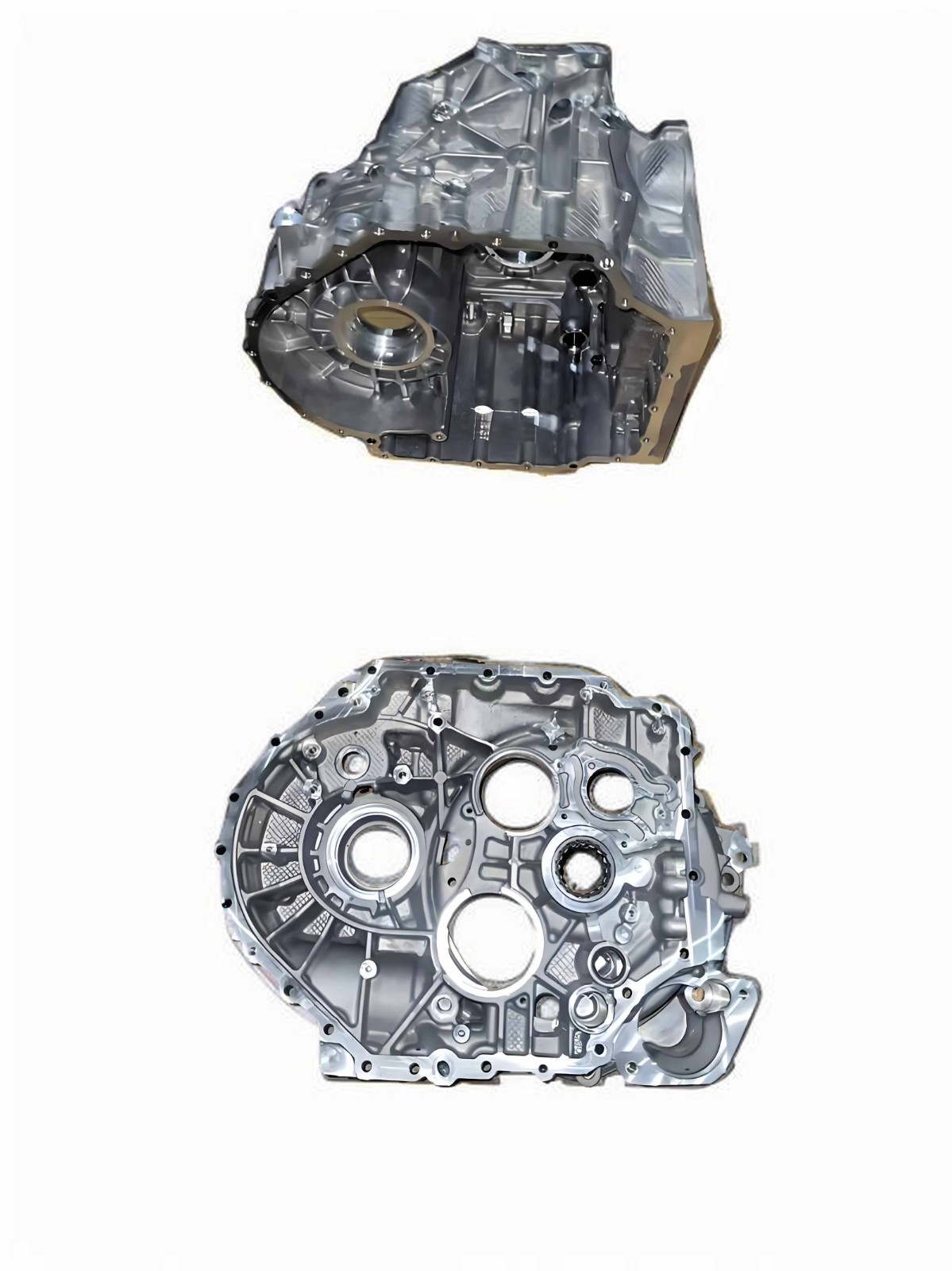

Introduction to Extension Housing

Extension housing, also known as the transmission extension or tail housing, is an essential component of a vehicle's drivetrain system. It connects the main transmission housing to the driveshaft, ensuring smooth power transfer from the engine to the wheels. Due to its critical role in vehicle performance and durability, the material and manufacturing process of extension housings are of utmost importance.

Aluminum casting has emerged as the preferred method for producing extension housings due to its exceptional properties, cost-effectiveness, and sustainability. This article explores how aluminum casting is revolutionizing the production of extension housings and why it is a preferred choice for Automotive Replacement parts.

Why Aluminum Casting for Extension Housing?

Aluminum casting is a manufacturing process that involves pouring molten aluminum into a mold to create complex and precise components. Here’s why aluminum casting is ideal for extension housings:

1. Lightweight Yet Durable:

Aluminum is significantly lighter than traditional materials like steel, reducing the overall weight of the vehicle. This contributes to improved fuel efficiency and better handling without compromising strength or durability.

2. High Precision and Complexity:

Aluminum casting allows for the production of intricate designs with tight tolerances. For extension housings, which require precise alignment for optimal drivetrain performance, this is a critical advantage.

3. Corrosion Resistance:

Aluminum’s natural resistance to corrosion makes it ideal for automotive applications. Extension housings are often exposed to harsh environments, and aluminum ensures longevity and reliability.

4. Thermal Conductivity:

Aluminum's excellent thermal conductivity helps dissipate heat generated during transmission operation, protecting the drivetrain components from overheating and ensuring consistent performance.

5. Cost-Effective Production:

Aluminum casting offers scalability, making it suitable for both mass production and custom Automotive Replacement parts. Its cost-effectiveness is a key factor in its widespread adoption.

The Role of Aluminum Casting in Automotive Replacement Parts

Automotive Replacement parts demand high-quality materials and manufacturing processes to ensure compatibility and performance. Extension housings are no exception. Whether replacing a worn-out part or upgrading an existing component, aluminum-cast extension housings provide several benefits:

- Enhanced Performance: Aluminum-cast extension housings deliver superior performance by reducing weight while maintaining strength.

- Sustainability: Aluminum is highly recyclable, making aluminum-cast extension housings an environmentally friendly choice.

- Custom Solutions: With aluminum casting, manufacturers can produce tailor-made extension housings that meet specific vehicle requirements.

Dongrun Casting Industry Co., Ltd specializes in producing high-quality aluminum-cast components for various automotive applications, including extension housings. Our expertise ensures that every product meets stringent industry standards.

Types of Aluminum Casting for Extension Housing

There are several aluminum casting methods suitable for manufacturing extension housings:

1. Die Casting:

Die casting involves injecting molten aluminum into a steel mold under high pressure. This process is ideal for high-volume production due to its speed and precision. Die-cast extension housings are known for their excellent surface finish and dimensional accuracy.

2. Sand Casting:

Sand casting uses a sand-based mold to create components. It is cost-effective for low-volume production or large-sized parts. Sand-cast extension housings are durable and can be customized to meet specific requirements.

3. Gravity Die Casting:

In gravity die casting, molten aluminum is poured into a mold using gravity. This method produces parts with superior mechanical properties and is suitable for medium-volume production.

4. Permanent Mold Casting:

This method uses reusable molds made of metal to produce high-quality components with consistent dimensions. Permanent mold casting is ideal for manufacturing precision extension housings with excellent strength.

Each method offers unique advantages depending on the application and production volume, allowing manufacturers to choose the best approach for their needs.

Quality Control in Aluminum Casting for Extension Housing

Ensuring the quality of aluminum-cast extension housings is critical for their performance and reliability. At Dongrun Casting Industry Co., Ltd, we implement strict quality control measures throughout the manufacturing process:

- Material Testing: We use high-grade aluminum alloys to ensure optimal strength, durability, and corrosion resistance.

- Dimensional Inspection:Advanced tools and techniques are employed to verify that each extension housing meets precise specifications.

- Non-Destructive Testing (NDT): Techniques like X-ray inspection are used to detect internal defects or porosity in castings.

- Performance Testing: Extension housings undergo rigorous testing to ensure they can withstand real-world conditions.

By adhering to these quality standards, we deliver products that exceed customer expectations and industry requirements.

Extension housing is a vital component in automotive systems, and aluminum casting has proven to be a game-changer in its production. With benefits like lightweight design, durability, cost-effectiveness, and sustainability, aluminum-cast extension housings are setting new standards in the industry.

Dongrun Casting Industry Co., Ltd is proud to be at the forefront of this innovation, offering high-quality aluminum-cast components tailored to meet diverse automotive needs. Whether you’re looking for reliable Automotive Replacement parts or custom solutions, our expertise ensures exceptional results every time.

For more information on our aluminum casting services or to explore our product range, visit our website today!

Factory Cabability

| Material | 1. Sand casting&Gravity casting&Low pressure die casting: |

| Service | Sand casting, Gravity casting, high pressure die casting,low pressure die casting and CNC Machining casting. |

Equipment of Casting | 1. High pressure die casting machining:125T/180T/250T/280T/500T/800T/1250T 2. Gravity casting machine: 7 production lines 3. Low pressure die casting machining: 1 production line 4. Sand casting machine: 6 production lines 5. Degassing equipment and opportunities to refine the material |

| Testing Facility | Spectrometer, Tensile test device, Hardness test device, CMM, X-Ray, Leaking test device |

Precision Machining | CNC turning, Milling, Drilling, Grinding, Cutting, Reaming and Threading |

| Finished | Polishing, Sand blasting, Heat treatment, Painting, Powder coating, Anodizing, Electroplating, Chrome plating, Mirror polishing. |

| Products | All kinds of Cast aluminum productions: Including Vehicle industry,Medical device industry, Marine industry, Lighting industry,Oil&Gas Transporttation industry, Electric Utility & Communication Industries, Architectural industry and Furniture industry so on |

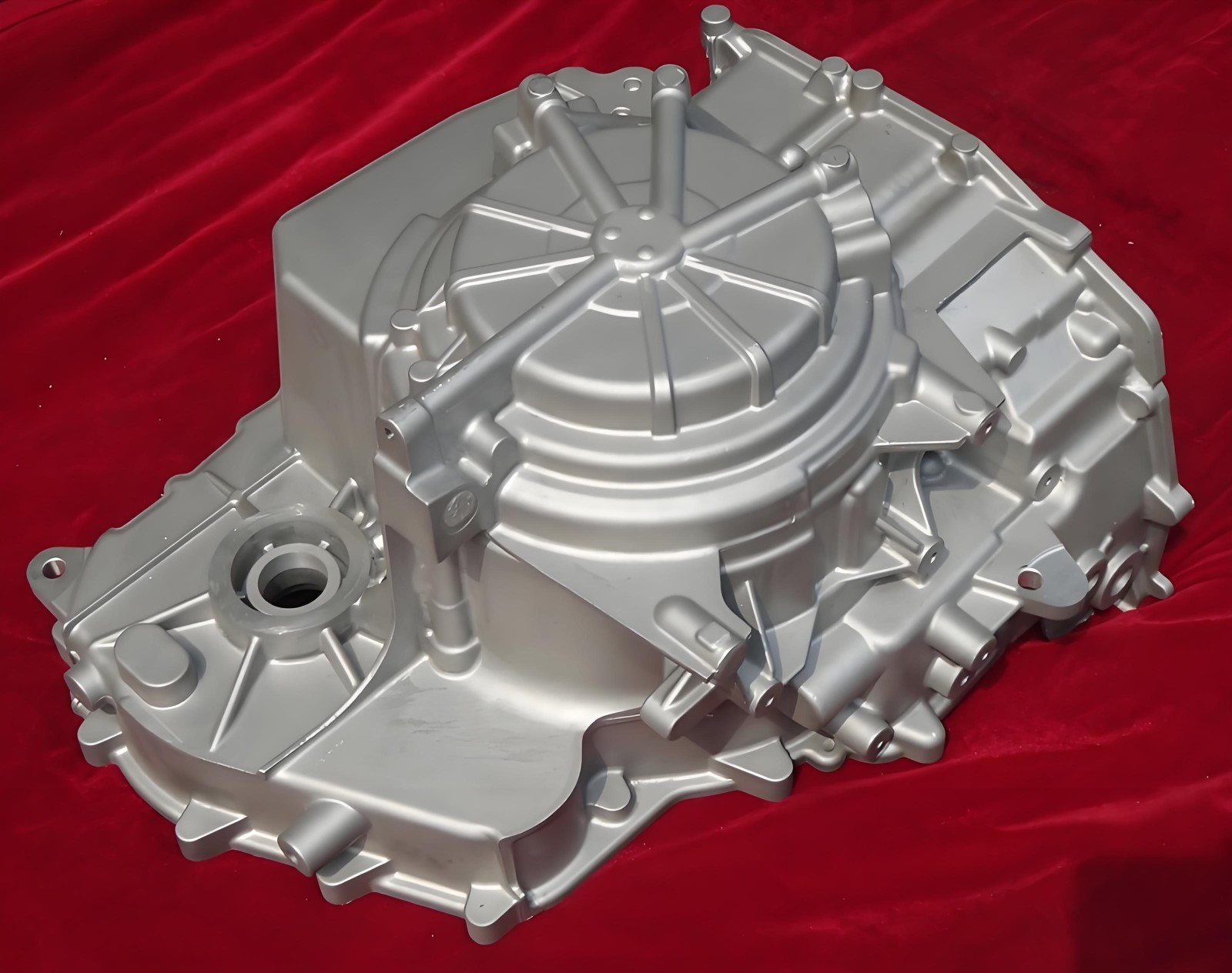

Production Images

|  |

Company Equipment

From Casting to Machining, One-stop Solutions for your designs

Packing & Shipping

Casting parts are very heavy, package must be strong. Our package material is wooden crate which is Fumigation free.

And we can pack productions as customers' requirements

Why Choose Us

❖ More than 25 years in castings and machining process; so we have much experience for your projects.

❖ Passed ISO9001 : 2015 & TS16949 : 2009

❖ Have four casting types in our factory; you can find the four process in one factory, save cost for your company

❖ From Casting to Finished surface, Owned casting, polishing and plating workshops, one-stop, We can offer Good quality and strict delivery time.

❖ With samples and order: We can offer dimension report, Chemical composition and Mechanical properties

❖ Control material with spectral and thermal analysis equipment (density and processing)

❖ Spectral analysis of raw material and liquid melt, batch before casting.

❖ Transportation Advantage:

A) Near Sea Port and Air Port-Ningbo Sea Port and Yiwu Airport or Hangzhou Airport;

B ) From Shanghai to our factory by Fast train directly, takes two and half hours; From Hangzhou to our factory, only takes one hour

FAQ

Q1. Are you trading company or manufacturer

We are factory, We are only doing cast aluminum and machining more than 20years, we have much experience in this industry. If you find some "factory" can do kinds of material castings(steel, iron,stainless,cooper.......), we are sure they are trading company. If you have other material castings to do, we can introduce for you free. It is our pleasure that we can help you.

Q2. How to get quotation from your factory?

We need a 3D CAD solid model to prepare a First Quote interactive quote. All of the Firstcut processes are dependent on good 3D CAD solid models. Two-dimensional (2D) drawings are not adequate for quoting or making parts.

We can accept native SolidWorks (.sldprt) or ProE (.prt) files as well as solid 3D CAD models from other CAD systems output in IGES (.igs), STEP (.stp), ACIS (.sat) or Parasolid (.x_t or .x_b) format.

Q3. When can I get the price?

We usually quote within 48 hours after we get your inquiry. If you are very urgent, please call us or tell us in your email so that we will regard your inquiry priority.

Q4. How about your lead time?

1): Toolings &Samples

Sand Casting will take 15 to 30 days after receiving your advance payment.

Gravity casting, low pressure die casting, high pressure die casting will take 30 to 60days after receiving your advance payment.

2) Mass production

The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings. We can build drawings for you after we get your samples too.

Q6. What is your sample policy?

We can supply 1pcs sample free (value under USD15/PCS) after we finish as your drawings, but the customers have to pay the freight cost. If you need more samples, you have to pay the samples cost.

Q7. Can we use your current tooling? Or can we get samples which are shown on your website?

No, we can't do it.

We only accept OEM orders and do casting parts as your drawings or samples. We can't sell any production or design to any third body. We can't show any photos on website without our clients' allowance. We signed NDA with all clients, all tooling and drawings belong our clients. We only use the tooling to make productions for one client. The client can take way the tooling any time after tooling cost.

Q8. Do you test all your goods before delivery?

Yes, we have 100% test before delivery

Q9: How do you make our business long-term and good relationship?

We keep good quality and competitive price to ensure our customers benefit ;

We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.