Product Description

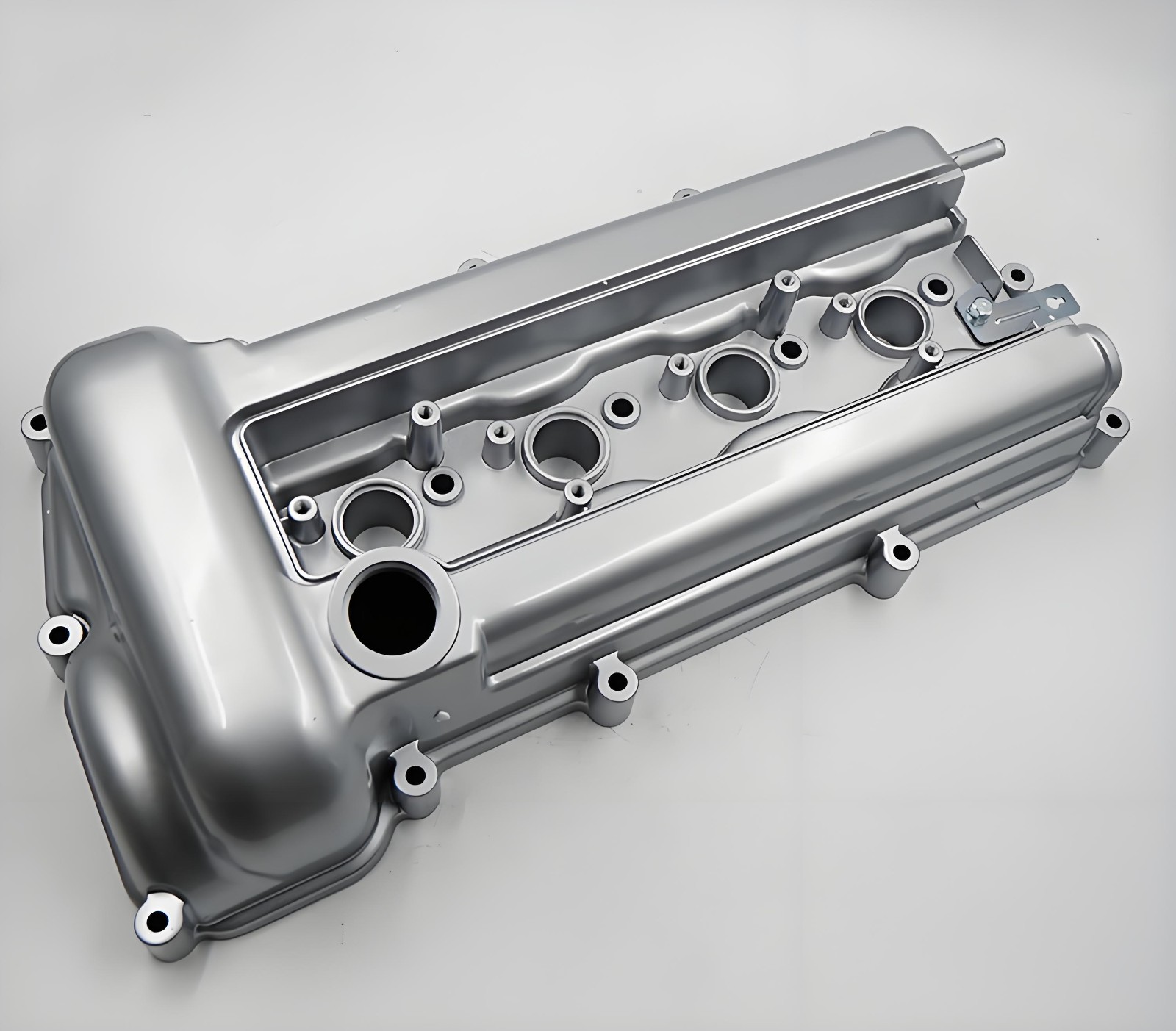

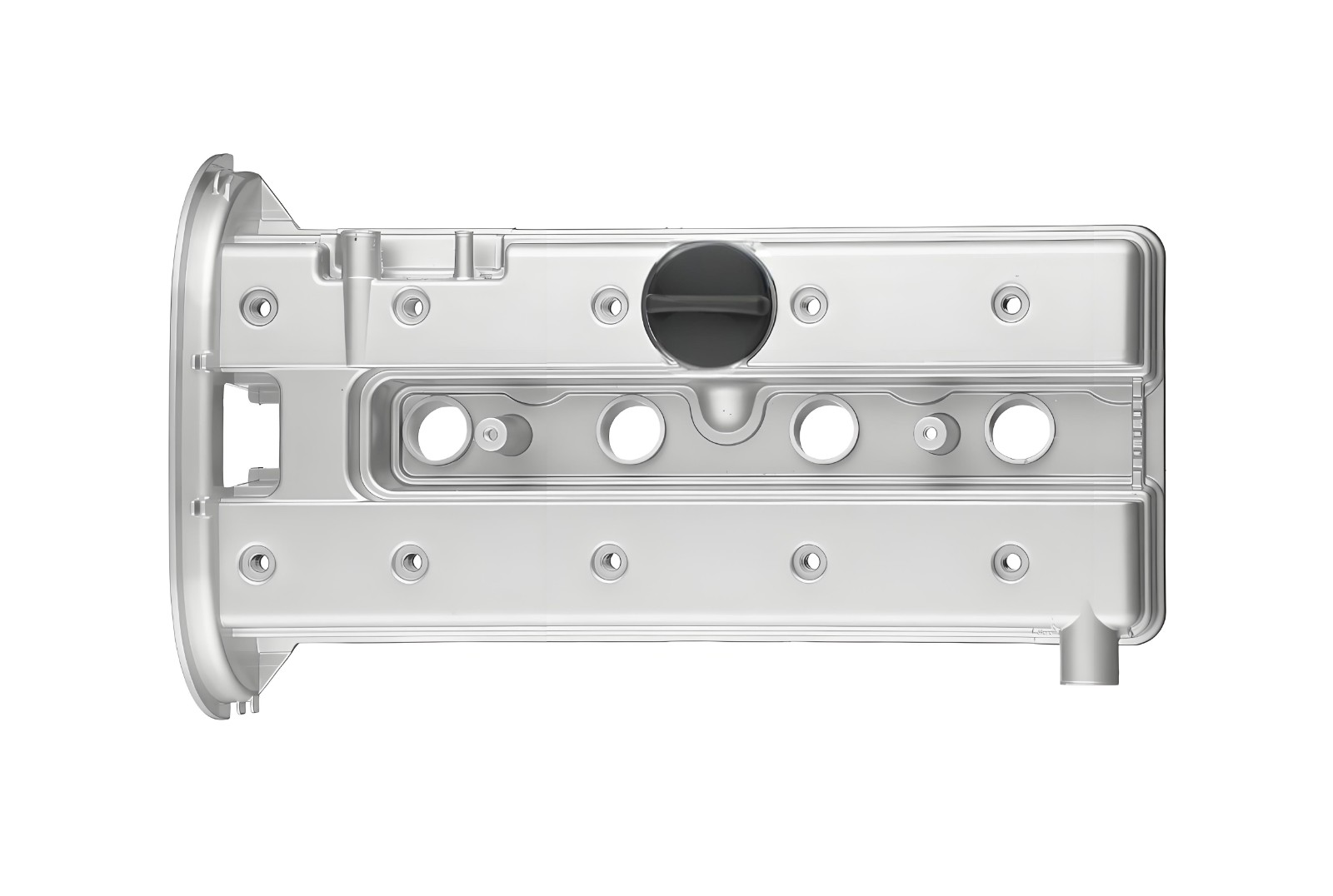

The Art of Aluminum Alloy Casting: A Focus on Rocker Covers

Rocker covers, also known as valve covers or rocker panel covers, are an essential component in automotive engineering, protecting the rocker arms and ensuring the proper functioning of internal combustion engines. With advancements in aluminum alloy casting technology, the manufacturing of rocker covers has become more efficient, durable, and lightweight. This article delves into the various aluminum casting techniques—such as aluminum sand casting, aluminum gravity casting, permanent mold aluminum casting, and low-pressure aluminum die casting—used in the production of high-quality aluminum alloy rocker covers. Additionally, we explore the benefits of aluminum as a material of choice and discuss the considerations for rocker panel replacement.

Introduction to Rocker Covers

Rocker covers play a vital role in protecting engine components from debris, dirt, and oil leakage. Traditionally made from steel or cast iron, modern rocker covers are increasingly manufactured using aluminum alloys due to their superior properties, including lightweight construction, corrosion resistance, and thermal conductivity. The shift toward aluminum alloy rocker covers has been driven by the automotive industry's demand for fuel efficiency and performance optimization.

When it comes to remanufacturing or replacing rocker panel covers, precision and quality are paramount. This is where advanced aluminum casting techniques come into play, ensuring that the final product meets stringent industry standards.

Aluminum Casting Techniques for Rocker Covers

1. Aluminum Sand Casting

Aluminum sand casting is one of the oldest and most versatile methods used in the production of rocker covers. In this process, a sand mold is created based on the desired shape of the rocker cover. Molten aluminum is then poured into the mold and allowed to cool. This technique is ideal for producing complex shapes and low-volume production runs.

Advantages:

- Cost-effective for small batches

- Suitable for intricate designs

- Short lead times

However, aluminum sand casting may not provide the surface finish or dimensional accuracy required for high-performance applications.

2. Aluminum Gravity Casting

Aluminum gravity casting involves pouring molten aluminum into a permanent mold under the force of gravity. This method is often used for manufacturing medium to high-volume parts like rocker covers due to its ability to produce components with excellent mechanical properties and surface finishes.

Advantages:

- High-quality surface finish

- Better dimensional accuracy compared to sand casting

- Suitable for medium production volumes

This technique is particularly useful when durability and strength are critical factors in rocker cover design.

3. Permanent Mold Aluminum Casting

Permanent mold aluminum casting uses reusable molds made of steel or other durable materials. Molten aluminum is poured into these molds, producing parts with consistent quality and minimal porosity. This method is ideal for high-volume production of aluminum alloy rocker covers.

Advantages:

- Excellent repeatability and consistency

- Superior mechanical properties

- Reduced material waste

The initial cost of creating permanent molds can be high, but this is offset by long-term cost savings in large-scale production.

4. Low-Pressure Aluminum Die Casting

Low-pressure aluminum die casting involves injecting molten aluminum into a mold using controlled pressure. This process ensures precise filling of the mold cavity, resulting in parts with exceptional strength and minimal defects. It is widely used for manufacturing lightweight yet durable rocker covers in modern vehicles.

Advantages:

- High production efficiency

- Excellent strength-to-weight ratio

- Minimal porosity

Low-pressure die casting is particularly suitable for producing thin-walled components like aluminum alloy rocker covers, which are essential for reducing vehicle weight without compromising strength.

Benefits of Aluminum Alloy Rocker Covers

1. Lightweight Construction

Aluminum alloys are significantly lighter than traditional materials like steel, contributing to improved fuel efficiency and reduced emissions in vehicles.

2. Corrosion Resistance

Aluminum's natural oxide layer offers excellent resistance to rust and corrosion, ensuring a longer lifespan for rocker covers even in harsh environments.

3. Thermal Conductivity

The high thermal conductivity of aluminum helps dissipate heat efficiently, maintaining optimal engine performance.

4. Recyclability

Aluminum is highly recyclable, making it an environmentally friendly choice for automotive applications.

Considerations for Rocker Panel Replacement

When replacing rocker panel covers or remanufacturing them, it is crucial to choose a method that aligns with the specific requirements of the application. Factors such as material properties, production volume, budget, and desired surface finish should be carefully evaluated. Additionally, partnering with an experienced aluminum casting expert ensures that the replacement parts meet or exceed OEM specifications.

The evolution of aluminum alloy casting techniques—such as aluminum sand casting, aluminum gravity casting, permanent mold aluminum casting, and low-pressure aluminum die casting—has revolutionized the production of rocker covers. These advanced methods enable manufacturers to produce high-quality components that are lightweight, durable, and cost-effective. As the automotive industry continues to prioritize sustainability and performance, aluminum alloy rocker covers will remain a cornerstone of modern engine design.

For automotive manufacturers or enthusiasts looking to replace or remanufacture rocker panel covers, understanding the nuances of aluminum casting processes can help make informed decisions that enhance both vehicle performance and longevity.

By leveraging cutting-edge casting technologies and the inherent benefits of aluminum alloys, the future of rocker cover manufacturing is poised to achieve new heights in efficiency and innovation.

Factory Cabability

| Material | 1. Sand casting&Gravity casting&Low pressure die casting: |

| Service | Sand casting, Gravity casting, high pressure die casting,low pressure die casting and CNC Machining casting. |

Equipment of Casting | 1. High pressure die casting machining:125T/180T/250T/280T/500T/800T/1250T 2. Gravity casting machine: 7 production lines 3. Low pressure die casting machining: 1 production line 4. Sand casting machine: 6 production lines 5. Degassing equipment and opportunities to refine the material 6. Machining: 9 Sets CNC Machines; 5 sets Milling machines; 3 setsTurning machines; 20 sets drill and tap machines |

| Testing Facility | Spectrometer, Tensile test device, Hardness test device, CMM, X-Ray, Leaking test device |

Precision Machining | CNC turning, Milling, Drilling, Grinding, Cutting, Reaming and Threading |

| Finished | Polishing, Sand blasting, Heat treatment, Painting, Powder coating, Anodizing, Electroplating, Chrome plating, Mirror polishing. |

| Products | All kinds of Cast aluminum productions: Including Vehicle industry,Medical device industry, Marine industry, Lighting industry,Oil&Gas Transporttation industry, Electric Utility & Communication Industries, Architectural industry and Furniture industry so on |

Production Images

|  |  |

Company Equipment

From Casting to Machining, One-stop Solutions for your designs

Packing & Shipping

Casting parts are very heavy, package must be strong. Our package material is wooden crate which is Fumigation free.

And we can pack productions as customers' requirements

Why Choose Us

❖ More than 25 years in castings and machining process; so we have much experience for your projects.

❖ Passed ISO9001 : 2015 & TS16949 : 2009

❖ Have four casting types in our factory; you can find the four process in one factory, save cost for your company

❖ From Casting to Finished surface, Owned casting, polishing and plating workshops, one-stop, We can offer Good quality and strict delivery time.

❖ With samples and order: We can offer dimension report, Chemical composition and Mechanical properties

❖ Control material with spectral and thermal analysis equipment (density and processing)

❖ Spectral analysis of raw material and liquid melt, batch before casting.

❖ Transportation Advantage:

A) Near Sea Port and Air Port-Ningbo Sea Port and Yiwu Airport or Hangzhou Airport;

B ) From Shanghai to our factory by Fast train directly, takes two and half hours; From Hangzhou to our factory, only takes one hour

FAQ

Q1. Are you trading company or manufacturer

We are factory, We are only doing cast aluminum and machining more than 20years, we have much experience in this industry. If you find some "factory" can do kinds of material castings(steel, iron,stainless,cooper.......), we are sure they are trading company. If you have other material castings to do, we can introduce for you free. It is our pleasure that we can help you.

Q2. How to get quotation from your factory?

We need a 3D CAD solid model to prepare a First Quote interactive quote. All of the Firstcut processes are dependent on good 3D CAD solid models. Two-dimensional (2D) drawings are not adequate for quoting or making parts.

We can accept native SolidWorks (.sldprt) or ProE (.prt) files as well as solid 3D CAD models from other CAD systems output in IGES (.igs), STEP (.stp), ACIS (.sat) or Parasolid (.x_t or .x_b) format.

Q3. When can I get the price?

We usually quote within 48 hours after we get your inquiry. If you are very urgent, please call us or tell us in your email so that we will regard your inquiry priority.

Q4. How about your lead time?

1): Toolings &Samples

Sand Casting will take 15 to 30 days after receiving your advance payment.

Gravity casting, low pressure die casting, high pressure die casting will take 30 to 60days after receiving your advance payment.

2) Mass production

The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings. We can build drawings for you after we get your samples too.

Q6. What is your sample policy?

We can supply 1pcs sample free (value under USD15/PCS) after we finish as your drawings, but the customers have to pay the freight cost. If you need more samples, you have to pay the samples cost.

Q7. Can we use your current tooling? Or can we get samples which are shown on your website?

No, we can't do it.

We only accept OEM orders and do casting parts as your drawings or samples. We can't sell any production or design to any third body. We can't show any photos on website without our clients' allowance. We signed NDA with all clients, all tooling and drawings belong our clients. We only use the tooling to make productions for one client. The client can take way the tooling any time after tooling cost.

Q8. Do you test all your goods before delivery?

Yes, we have 100% test before delivery

Q9: How do you make our business long-term and good relationship?

We keep good quality and competitive price to ensure our customers benefit ;

We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.